loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Utilizing FRP Bars for Enhanced Reinforcement in Concrete Structures

The Role of FRP Bars in Concrete Structures

Fiber Reinforced Polymer (FRP) bars have emerged as a revolutionary alternative to traditional steel reinforcement in concrete structures. Their unique properties and advantages make them an attractive choice for engineers and builders alike. As infrastructure demands grow and the need for sustainable building materials intensifies, understanding the role of FRP bars in concrete is essential.

What Are FRP Bars?

FRP bars are made from composite materials, typically consisting of a polymer matrix reinforced with fibers such as glass, carbon, or aramid. These bars possess excellent mechanical properties, including high tensile strength and low weight compared to steel. Furthermore, they exhibit superior resistance to environmental factors such as corrosion, making them an ideal choice for structures exposed to harsh conditions.

Advantages of FRP Bars

1. Corrosion Resistance One of the most compelling advantages of FRP bars is their resistance to corrosion. Traditional steel reinforcements are susceptible to rust when exposed to moisture, leading to structural weakening over time. In contrast, FRP bars do not corrode, significantly extending the lifespan of concrete structures, especially in marine environments or locations with de-icing salts.

2. Lightweight The reduced weight of FRP bars facilitates easier handling and installation. Engineers can design structures that require less support and can still accommodate high loads. This characteristic can also reduce transportation costs and labor expenses on-site.

3. High Strength-to-Weight Ratio FRP bars boast a higher strength-to-weight ratio than steel; they provide equivalent or superior tensile strength while being significantly lighter. This property allows for innovative design options, enabling the construction of slenderer structural elements.

4. Non-Magnetic and Non-Conductive FRP bars do not conduct electricity, making them suitable for use in structures that require electromagnetic neutrality, such as in hospitals or sensitive electronic environments. Their non-magnetic properties make them ideal for applications like bridges, where magnetic interference must be minimized.

5. Sustainability Given the increasing emphasis on sustainable materials in construction, FRP bars offer a compelling choice. Their longevity reduces the need for repairs and replacements, contributing to a lower carbon footprint over the life cycle of a structure. Moreover, many FRP materials are derived from renewable sources.

frp bars in concrete

Applications of FRP Bars

The unique properties of FRP bars allow their application in various structures. Common uses include

- Bridges Due to their lightweight nature and corrosion resistance, FRP bars are increasingly utilized in bridge decks and superstructures. Their application can extend the service life of bridges, reducing the frequency of maintenance.

- Parking Structures Parking garages are often subjected to exposure from vehicles and road salts. By using FRP bars, these structures can resist damage from corrosive elements, thus enhancing their durability.

- Marine Structures Harbor facilities, piers, and seawalls benefit since FRP’s resistance to seawater offers significant advantages over traditional materials.

- Buildings In residential and commercial construction, FRP bars can be integrated into slabs, walls, and other elements to improve structural integrity while decreasing overall weight.

Challenges and Considerations

Despite the myriad advantages, there are challenges to consider when using FRP bars. The initial material and installation cost of FRP can be higher than that of traditional steel reinforcement. Additionally, design codes and standards for FRP-reinforced structures are still evolving. Engineers must ensure adequate training to adapt to the specific challenges posed by these materials.

Conclusion

In summary, FRP bars represent a significant advancement in concrete reinforcement technology. Their corrosion resistance, lightweight nature, high strength-to-weight ratio, and suitability for sustainable applications position them as a viable alternative to traditional steel bars. As the construction industry continues to evolve, the integration of FRP bars will likely increase, pushing the boundaries of what is achievable in modern architecture and infrastructure. For engineers dedicated to enhancing the durability and sustainability of their projects, FRP bars offer a promising solution worthy of consideration.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

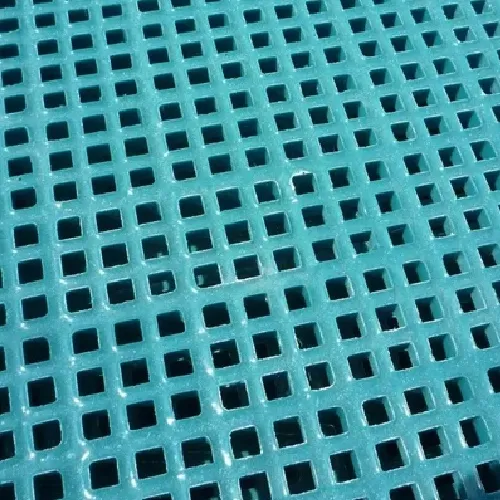

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025