loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

The Use of FRP Bars for Enhanced Concrete Reinforcement and Structural Performance

Fiber Reinforced Polymer (FRP) Bars in Concrete A Comprehensive Insight

In recent years, the construction industry has witnessed a significant shift towards using innovative materials to enhance the performance and longevity of structures. Among these materials, Fiber Reinforced Polymer (FRP) bars have emerged as a prominent alternative to traditional steel reinforcement. Comprising a composite material made of high-strength fibers embedded in a polymer matrix, FRP bars offer unique advantages in various concrete applications.

Fiber Reinforced Polymer (FRP) Bars in Concrete A Comprehensive Insight

Another notable advantage of FRP bars is their high tensile strength-to-weight ratio. This property not only makes them lighter than traditional steel reinforcement but also allows for greater design flexibility in constructing a variety of structures. Engineers can leverage this feature to create innovative designs that were previously challenging or impossible to achieve with steel reinforcement. Additionally, the lower weight of FRP bars can simplify transportation and handling, further streamlining the construction process.

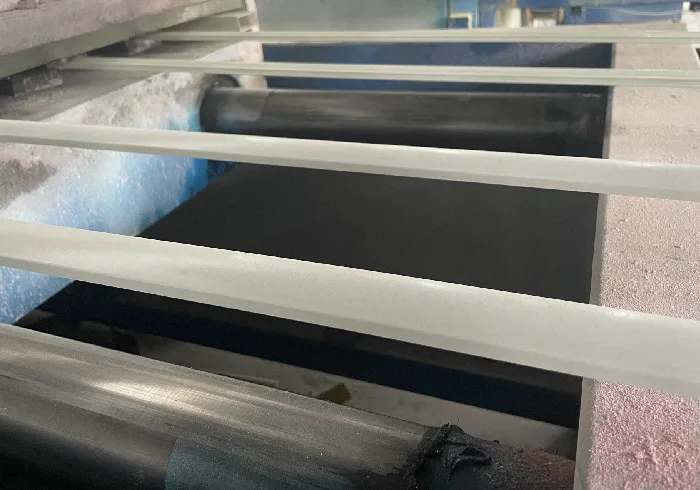

frp bars in concrete

Moreover, FRP bars are non-magnetic and non-conductive, making them ideal for certain specialized applications. In structures where electromagnetic interference is a concern, such as in transportation systems or sensitive electronic installations, FRP bars can be utilized without negatively impacting the performance of the overall system. This unique property opens up new avenues for engineers to explore the use of FRP in a wider array of projects.

Despite their numerous advantages, the adoption of FRP bars in concrete structures also presents certain challenges. For instance, the bond strength between FRP bars and concrete can be less than that between steel and concrete. This can lead to complications in load transfer and potential premature failure if not addressed during design and construction. Engineers must carefully consider these factors and conduct thorough analyses to ensure the successful implementation of FRP bars in their projects.

Furthermore, the initial cost of FRP bars is generally higher than that of traditional steel reinforcement. However, when evaluating the life-cycle costs, including the reduced need for maintenance and repairs over time, FRP bars can prove to be an economically viable choice. As the industry continues to evolve, advancements in manufacturing processes and increased demand for sustainable construction materials may lead to cost reductions, making FRP bars more accessible for wider use.

In conclusion, Fiber Reinforced Polymer bars represent a significant advancement in concrete reinforcement technology. With their corrosion resistance, high strength, lightweight nature, and versatility, they offer numerous benefits for modern construction projects. While challenges remain, ongoing research and development in this field promise to enhance the performance and applicability of FRP bars. Ultimately, as the construction industry embraces these innovative materials, FRP bars may play a pivotal role in shaping the future of infrastructure engineering, creating structures that are not only stronger but also more sustainable and resilient. As we move towards a more environmentally conscious approach in construction, the integration of FRP bars into concrete applications will likely become increasingly prevalent, paving the way for a new era of building technology.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025