loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

frp vessel price

Understanding the Pricing of FRP Vessels

Fiber Reinforced Plastic (FRP) vessels have gained significant traction across industries due to their lightweight, corrosion-resistant, and durable characteristics. This growing demand has led many businesses to explore the pricing dynamics of FRP vessels, which can vary considerably based on several factors. Understanding these factors can help organizations make informed purchasing decisions.

Key Factors Influencing FRP Vessel Pricing

1. Material Composition The primary materials used in manufacturing FRP vessels, such as fiberglass, resins, and additives, play a crucial role in determining the cost. Higher-quality materials, which provide better strength, durability, and resistance to environmental factors, tend to raise the price. For instance, vessels made with vinyl ester resin are generally more expensive than those made with standard polyester due to their superior properties.

Understanding the Pricing of FRP Vessels

3. Manufacturing Process The method used to produce the FRP vessel is another critical aspect affecting pricing. Techniques such as hand lay-up, spray-up, and filament winding differ in terms of labor and material costs. Automated processes can reduce production time and minimize human error, which may lead to cost savings. However, the initial investment in technology can also contribute to higher prices for vessels produced with advanced methods.

frp vessel price

4. Market Demand and Supply Just like any other product, the price of FRP vessels is susceptible to market dynamics. A surge in demand, driven by advancements in industries like chemical storage and water treatment, can elevate prices. Conversely, an oversupply of FRP vessels, perhaps due to market saturation or economic downturns, may cause prices to drop.

5. Regulatory Compliance Industries often have stringent safety and environmental regulations that FRP vessels must adhere to. Compliance with these regulations can lead to increased production costs, which are subsequently reflected in pricing. For example, vessels intended for use in hazardous environments may require additional certifications, thereby inflating costs.

6. Geographic Factors The location of production facilities can also impact prices. Shipping costs, tariffs, and local market conditions play significant roles. For instance, sourcing raw materials from remote regions or transporting fully manufactured vessels across long distances can contribute to increased overall expenses.

Conclusion

In summary, the pricing of FRP vessels is influenced by a multitude of factors, including material quality, design complexity, manufacturing processes, market dynamics, regulatory compliance, and geographic considerations. For businesses looking to invest in FRP vessels, understanding these elements is crucial for making informed decisions. As the demand for FRP products continues to grow, staying informed about these pricing factors will be essential for securing cost-effective and high-quality vessels tailored to specific needs. Choosing the right supplier and negotiating based on a comprehensive understanding of market conditions can lead to substantial savings and optimal performance in various applications.

-

Premium FRP Handrail for All ApplicationsNewsAug.29,2025

-

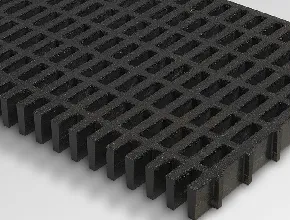

Low Maintenance FRP Mini Mesh Grating ProductsNewsAug.29,2025

-

Innovative FRP Square Tubes for Modern Industrial SolutionsNewsAug.29,2025

-

FRP Water Storage Tanks Wholesale Solutions for Bulk BuyersNewsAug.29,2025

-

FRP Molded Grating Solutions for Diverse Industrial ApplicationsNewsAug.29,2025

-

Construction Advancements Through FRP Pultruded ProfilesNewsAug.29,2025

-

Why Choose FRP Railings, Guardrails, and Handrail Systems?NewsAug.29,2025