loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

frp vessel for water treatment

The Role of FRP Vessels in Water Treatment

Fiber-reinforced plastic (FRP) vessels have become an increasingly popular choice in the water treatment industry due to their remarkable properties and advantages. These vessels are constructed using composite materials, which typically consist of a plastic matrix reinforced with fibers, such as glass or carbon. This combination provides a unique set of features that make FRP vessels suitable for various water treatment applications.

The Role of FRP Vessels in Water Treatment

In addition to corrosion resistance, FRP vessels are lightweight yet strong. This characteristic simplifies the installation process and reduces transportation costs. For example, when compared to stainless steel vessels, FRP vessels can weigh significantly less while maintaining structural integrity under pressure. This feature not only saves costs but also facilitates the implementation of water treatment systems in locations that may not support heavier equipment.

frp vessel for water treatment

Another compelling aspect of FRP vessels is their versatility in design. Manufacturers can engineer these vessels to meet specific capacity needs and operational requirements. Whether for filtration, ion exchange, or chemical storage, FRP vessels can be customized in terms of size, shape, and internal configurations. This flexibility allows water treatment facilities to optimize their processes and improve overall efficiency.

Moreover, FRP vessels exhibit excellent thermal insulation properties. They can help maintain temperature stability within the vessel, which is critical for certain water treatment processes where temperature fluctuations can impact efficiency. Additionally, the smooth interior surface of FRP vessels minimizes biofouling and scaling, further enhancing operational effectiveness.

Sustainability is also a crucial consideration in modern water treatment solutions. FRP vessels can contribute to more sustainable practices, as they are often designed to have a longer lifespan, reducing the frequency of replacements. Furthermore, many manufacturers are increasingly focusing on environmentally friendly production methods, making it possible for FRP vessels to align with sustainable development goals.

In conclusion, FRP vessels play a vital role in the water treatment industry due to their corrosion resistance, lightweight nature, design flexibility, thermal insulation, and durability. These advantages make FRP an excellent choice for a variety of applications, ranging from municipal drinking water treatment to industrial wastewater management. As the demand for efficient and reliable water treatment solutions continues to rise, the utilization of FRP vessels is poised to increase, transforming how we approach this critical resource management challenge.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

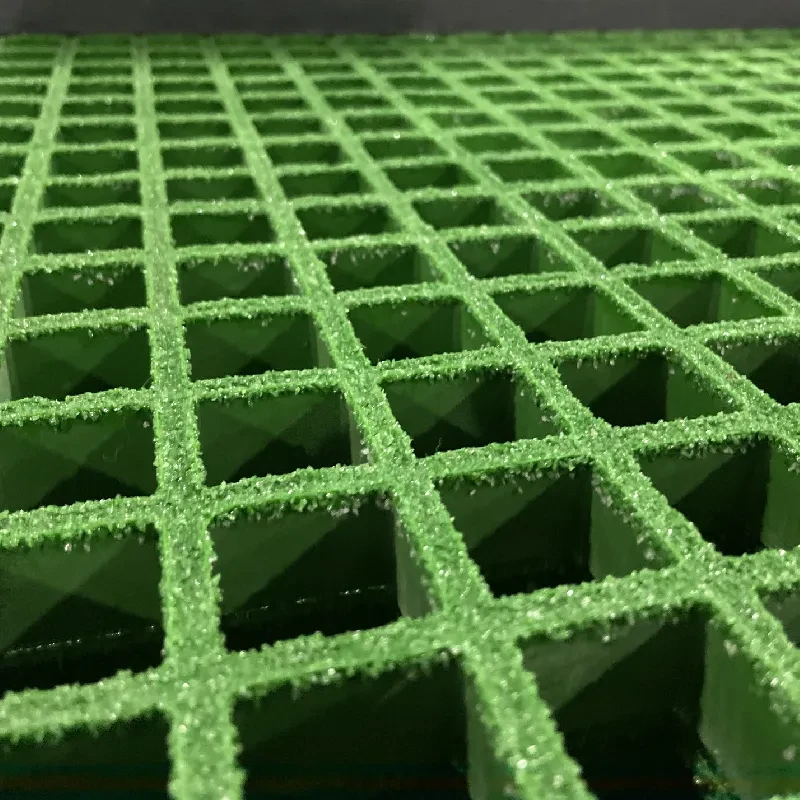

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025