loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

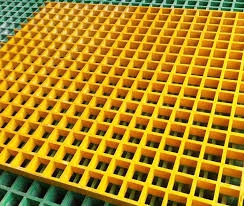

FRP Structural Members - Lightweight & Durable Solutions

Understanding FRP Structural Members A Modern Solution for Engineering Challenges

Fiber Reinforced Polymer (FRP) materials have increasingly gained importance in modern engineering and construction due to their lightweight, high strength, and corrosion-resistant properties. FRP structural members are revolutionizing the way we approach design and construction in various sectors, including civil engineering, aerospace, and marine applications. This article delves into the characteristics, advantages, and applications of FRP structural members.

FRP is composed of a polymer matrix reinforced with fibers, typically glass, carbon, or aramid. This composite material combines the advantageous properties of both the matrix and the reinforcement. The result is an incredibly versatile material that can be molded into various shapes and sizes while maintaining excellent mechanical properties. One of the most significant benefits of FRP is its impressive strength-to-weight ratio. This feature allows for the design of lighter structures without compromising strength, which is particularly advantageous in applications where weight constraints are critical.

Understanding FRP Structural Members A Modern Solution for Engineering Challenges

Furthermore, FRP materials exhibit excellent thermal and electrical insulation properties. This characteristic reduces the risk of thermal bridges and enhances energy efficiency in building designs. Moreover, the non-conductive nature of FRP makes it suitable for applications where electrical isolation is required, such as in electrical enclosures and power lines.

frp structural members

The manufacturing process of FRP structural members allows for a high degree of customization. Components can be designed specifically to meet the unique requirements of different projects. This flexibility facilitates innovative designs that were not feasible with traditional materials. Additionally, the prefabrication of FRP elements can significantly reduce construction time and labor costs, further benefiting project timelines and budgets.

Applications of FRP structural members are diverse and continually expanding. In civil engineering, FRP is used for bridge construction, retrofitting aging infrastructure, and building facades. Its lightweight nature and ease of installation make it an appealing option for new constructions and renovations. In the aerospace industry, FRP components play a critical role in the design of lightweight aircraft that improve fuel efficiency and performance. Marine applications also benefit from FRP’s resistance to corrosion, with many boat manufacturers incorporating FRP in their designs for hulls and other structural components.

Despite its numerous advantages, the use of FRP structural members does come with challenges, such as higher initial material costs and the need for specialized knowledge in design and construction. However, the long-term benefits, including extensive durability and lower maintenance costs, often outweigh these initial hurdles.

In conclusion, FRP structural members represent a significant advancement in engineering materials, offering unique properties that enhance the performance and longevity of structures. As technology continues to evolve, the adoption of FRP is likely to grow, leading to even more innovative applications and solutions in the construction industry and beyond.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025