loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

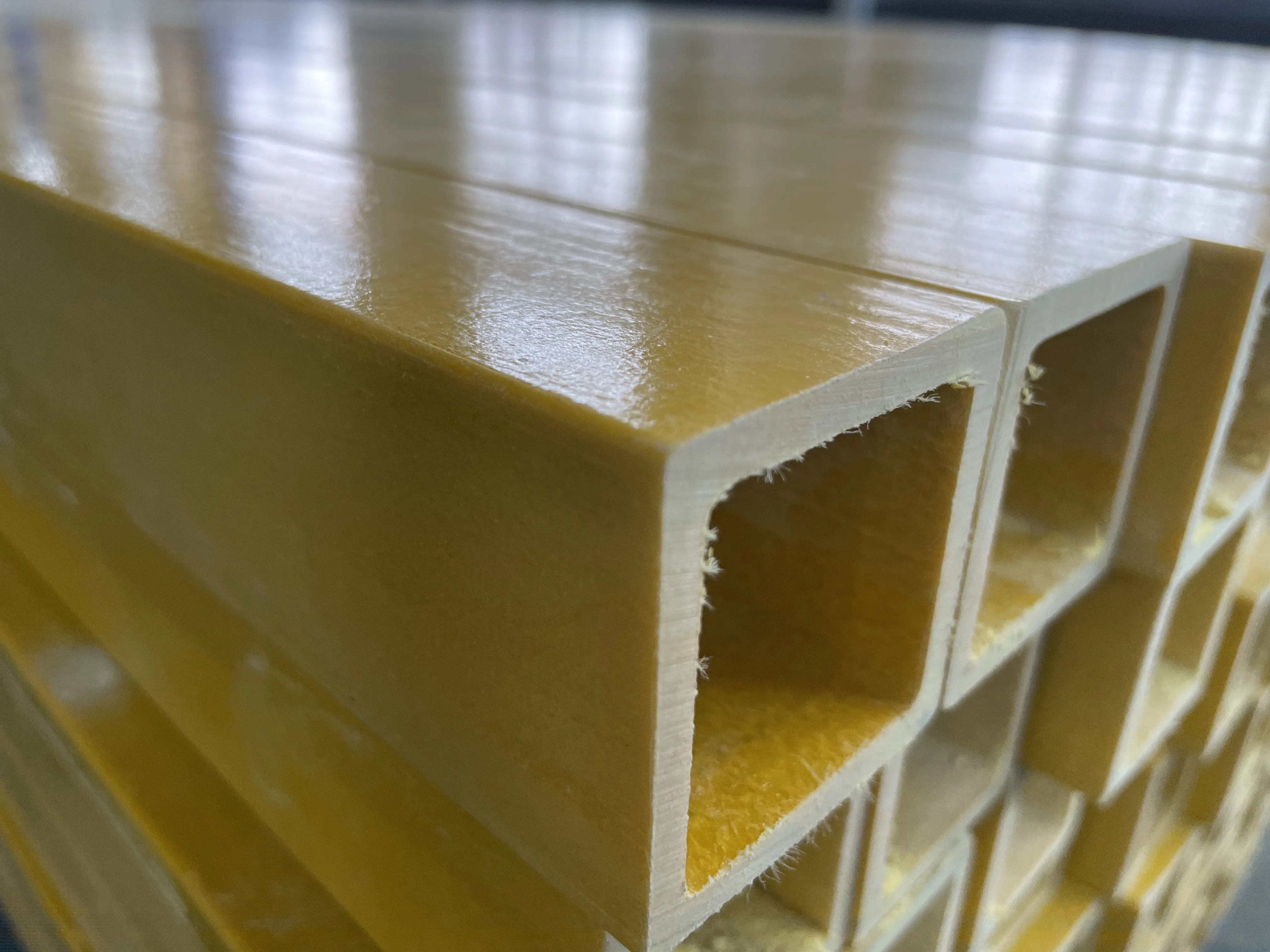

High-Quality FRP Square Tubes for Versatile Applications

Understanding FRP Square Tubes Material Properties and Applications

Fiber Reinforced Polymer (FRP) square tubes have gained significant attention in various industries due to their outstanding material properties and versatility. Composed of a polymer matrix reinforced with fibers such as glass, carbon, or aramid, FRP materials are renowned for their lightweight nature, high strength-to-weight ratios, and exceptional corrosion resistance. These characteristics make FRP square tubes an ideal choice for diverse applications ranging from construction to automotive and aerospace sectors.

Understanding FRP Square Tubes Material Properties and Applications

In construction, FRP square tubes are increasingly used in building frameworks, reinforcement, and architectural elements. Since they are non-conductive and non-magnetic, these materials are favorable in areas where electrical interference is a concern. Their resilience against harsh environmental conditions, such as salty air or extreme temperatures, makes them suitable for coastal or industrial applications. For instance, FRP square tubes can be utilized in bridges, walkways, and support structures, providing long-lasting durability and safety.

frp square tube

Moreover, in the automotive industry, weight reduction is crucial for enhancing fuel efficiency and performance. FRP square tubes can replace heavier metal components, contributing significantly to reducing overall vehicle weight without compromising strength. This development not only benefits performance but also leads to lower emissions, aligning with the automotive industry's shift towards sustainability.

Additionally, the aerospace sector has also embraced FRP square tubes due to their high strength, lightweight characteristics, and resistance to harsh operating environments. These tubes can be found in various components such as fuselages, wing structures, and space equipment, where every ounce matters in terms of efficiency and performance.

Manufacturing processes for FRP square tubes can include pultrusion, where continuous fibers are drawn through a resin bath and then shaped, or filament winding, where fibers are wound around a mold. These methods ensure precise control over the material properties and the ability to produce tubes in various sizes and specifications, catering to specific application requirements.

In conclusion, FRP square tubes represent a significant advancement in material technology, providing a lightweight, durable, and corrosion-resistant solution for a myriad of applications. As industries continue to seek innovative ways to improve performance and efficiency, the role of FRP square tubes will undoubtedly expand, paving the way for future developments in engineering and design.

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025

-

The Strength and Durability of FRP GratingNewsMay.21,2025

-

The Importance of Water Treatment Systems for Clean and Safe WaterNewsMay.21,2025

-

The Advantages of FRP Rebar for Construction ProjectsNewsMay.21,2025

-

Say Goodbye to Hard Water with a Reliable Water SoftenerNewsMay.21,2025

-

Maximize Your Water Storage with a Sectional Water TankNewsMay.21,2025

-

The Power of Filter VesselsNewsMay.19,2025