loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

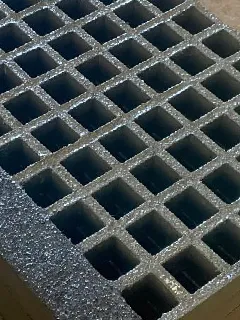

High-Performance FRP Pultruded Sections for Versatile Applications

Understanding FRP Pultruded Sections A Modern Solution for Structural Applications

Fiber-Reinforced Polymer (FRP) pultruded sections have emerged as a groundbreaking solution in various structural applications, combining strength, durability, and lightweight properties. The pultrusion process, a continuous manufacturing method, enables the production of composite materials that can outperform traditional materials such as steel and aluminum in many scenarios.

The pultrusion method begins with the impregnation of fibers, typically glass, carbon, or aramid, with a thermosetting resin like epoxy or polyester. These fibers are then drawn through a heated die, which shapes and cures the resin, forming solid, continuous lengths of FRP sections. This manufacturing process results in products with enhanced mechanical properties, including high tensile and compressive strength, resistance to corrosion, and minimal thermal expansion.

Understanding FRP Pultruded Sections A Modern Solution for Structural Applications

Furthermore, the lightweight nature of FRP pultruded sections dramatically simplifies handling and installation. These materials can be up to five times lighter than steel, reducing the need for heavy equipment during installation and allowing for easier transport. This characteristic makes FRP an ideal choice for retrofitting existing structures, where minimizing additional load is critical.

frp pultruded sections

In terms of design flexibility, FRP pultruded sections can be easily molded into intricate shapes and sizes, accommodating a diverse range of architectural and engineering requirements. This adaptability allows for innovative designs that can meet both aesthetic and functional demands, paving the way for stunning structures that were once considered impractical.

Moreover, the low thermal conductivity of FRP reduces heat transfer, contributing to energy efficiency in buildings. This is particularly beneficial in areas with extreme climates, where maintaining stable indoor temperatures can lead to significant energy savings.

Despite their numerous advantages, it is essential to recognize that, like any material, FRP pultruded sections come with specific considerations. Engineers must take into account factors such as fire resistance, UV degradation, and potential impact damage. However, with advancements in technology and a deeper understanding of composite materials, these challenges can be effectively addressed.

In conclusion, FRP pultruded sections stand out as a modern solution that bridges the gap between traditional construction materials and the demands of contemporary infrastructure. With their remarkable strength-to-weight ratio, resistance to environmental factors, and design versatility, they are poised to play a pivotal role in the future of construction and engineering. As industries continue to innovate and seek sustainable alternatives, FRP pultruded sections will undoubtedly be at the forefront of this evolution, setting new standards for performance and reliability.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025