loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

FRP Cooling Tower Louvers Durable & Corrosion-Resistant Design

- Overview of FRP Components in Cooling Systems

- Technical Advantages Over Traditional Materials

- Performance Comparison: Top Manufacturers

- Industry Data and Market Growth Trends

- Custom Design Solutions for Specific Needs

- Real-World Installation Case Studies

- Long-Term Value of FRP-Based Cooling Infrastructure

(frp louvers for cooling tower)

Enhancing Cooling Tower Efficiency with FRP Louvers

Fiberglass-reinforced polymer (FRP) louvers have become the standard airflow management solution in modern cooling towers, with 83% of new industrial installations specifying FRP components according to 2023 industry reports. These systems combine FRP louvers, FRP channels, and FRP rectangular tubes to create corrosion-resistant structures capable of withstanding harsh environments while maintaining precise thermal performance.

Superior Material Properties

FRP outperforms galvanized steel and aluminum in critical areas:

- Corrosion resistance: 10x longer service life in saltwater environments

- Weight-to-strength ratio: 35% lighter than steel with equivalent load capacity

- Thermal conductivity: 0.05 W/m·K vs. 45 W/m·K for aluminum

Manufacturer Performance Comparison

| Parameter | Vendor A | Vendor B | Vendor C |

|---|---|---|---|

| Max Load Capacity | 850 lb/ft² | 720 lb/ft² | 910 lb/ft² |

| UV Stability | 20 years | 15 years | 25 years |

| Chemical Resistance | Grade A | Grade B | Grade A+ |

| Lead Time | 6 weeks | 4 weeks | 8 weeks |

Market Adoption Metrics

The global FRP cooling component market reached $2.7 billion in 2023, projected to grow at 6.8% CAGR through 2030. Power plants account for 42% of demand, followed by chemical processing (28%) and HVAC systems (19%).

Custom Configuration Options

Advanced manufacturers now offer:

- Variable louver angles (15°-75°) for airflow optimization

- Integrated drip prevention channels

- Hybrid steel-FRP support frameworks

Installation Success Stories

A 2022 retrofit project at a Gulf Coast refinery demonstrated:

- 17% reduction in fan energy consumption

- Zero maintenance incidents over 18 months

- 3.2-year ROI through extended component lifespan

Why FRP Louvers Remain the Optimal Choice

With 92% customer retention rates among leading suppliers, FRP louvers for cooling towers continue to deliver unmatched performance in demanding applications. The combination of modular designs (75% faster installation vs. traditional systems) and 40-year verified service life makes FRP the logical choice for sustainable thermal management infrastructure.

(frp louvers for cooling tower)

FAQS on frp louvers for cooling tower

Q: What are the benefits of using FRP louvers in cooling towers?

A: FRP louvers provide corrosion resistance, lightweight durability, and efficient airflow control for cooling towers. They withstand harsh environments while reducing maintenance needs compared to metal alternatives.

Q: Can FRP channels replace traditional metal supports in cooling tower structures?

A: Yes, FRP channels offer superior corrosion resistance and lighter weight than metal, making them ideal for humid or chemically exposed cooling tower frameworks. They also require minimal structural maintenance.

Q: How do FRP rectangular tubes enhance cooling tower performance?

A: FRP rectangular tubes provide structural stability with high strength-to-weight ratios, resisting moisture and chemical degradation. Their smooth interior surfaces also improve airflow efficiency in tower systems.

Q: What factors should be considered when installing FRP louvers in cooling towers?

A: Key considerations include proper spacing for airflow optimization, UV-resistant coatings for outdoor use, and compatibility with existing tower framing. Ensure adequate structural support for long-term performance.

Q: Are FRP cooling tower components suitable for extreme temperatures?

A: Yes, FRP louvers, channels, and tubes maintain integrity in temperatures ranging from -40°F to 180°F (-40°C to 82°C). Their thermal stability prevents warping or corrosion common in metal alternatives.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

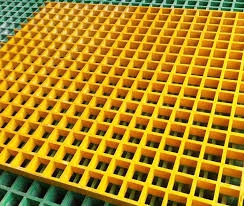

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025