loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

frp c channel

Understanding FRP C Channels A Comprehensive Overview

Fiber Reinforced Polymer (FRP) C channels have emerged as a significant innovation in the field of construction and engineering. Combining the benefits of lightweight materials with high strength and durability, FRP C channels are increasingly being adopted in various applications, from building infrastructure to automotive components.

What is FRP?

FRP is a composite material made from a polymer matrix reinforced with fibers, typically glass, carbon, or aramid. This combination results in materials that exhibit exceptional strength-to-weight ratios, corrosion resistance, and flexibility in design. One of the most popular shapes in the FRP category is the C channel, which provides structural support while maintaining lightweight characteristics.

Advantages of FRP C Channels

1. Corrosion Resistance One of the primary advantages of FRP C channels is their resistance to corrosion. Unlike steel and other conventional materials that rust and degrade over time, FRP does not corrode when exposed to harsh environmental conditions, making it ideal for use in marine, chemical, and wastewater treatment applications.

2. Lightweight and Strong The combination of fibers and polymers results in an incredibly strong yet lightweight material. This characteristic not only facilitates easier handling and installation but also offers significant advantages in structural applications where weight reduction is critical.

3. Design Flexibility FRP C channels can be manufactured in various sizes and configurations, allowing engineers and architects to customize their designs to meet specific project requirements. This versatility makes them suitable for a wide range of applications across different industries.

4. Thermal and Electrical Insulation Unlike metals, FRP materials provide excellent thermal and electrical insulation. This property is crucial in applications where thermal conductivity or electrical safety is a concern.

frp c channel

5. Lower Lifecycle Costs While the initial investment in FRP C channels may be higher than traditional materials, the long-term savings from reduced maintenance and replacement costs often make them a more economical choice over time.

Applications of FRP C Channels

FRP C channels are used in various sectors, including

- Construction In structures exposed to moisture and chemicals, such as bridges, piers, and raised walkways, FRP C channels provide lasting support. - Transportation The automotive industry utilizes FRP C channels for lightweight components, enhancing fuel efficiency without compromising structural integrity.

- Aerospace In aerospace applications, weight reduction is paramount. Utilizing FRP C channels contributes to lighter aircraft, leading to improved performance and fuel savings.

- Wind Energy The renewable energy sector, particularly wind turbines, benefits from the use of FRP due to its low weight and high strength, promoting more efficient energy generation.

Conclusion

FRP C channels are revolutionizing the way engineers approach structural design and material selection. Their unique combination of strength, lightweight characteristics, and resistance to environmental factors makes them an excellent choice for modern applications across various industries. As technology advances and production methods improve, the use of FRP materials is expected to grow, further solidifying their place in the future of engineering and construction. Whether it's paving the way for more resilient infrastructures or enabling innovations in transportation, FRP C channels represent a significant advancement in materials science.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

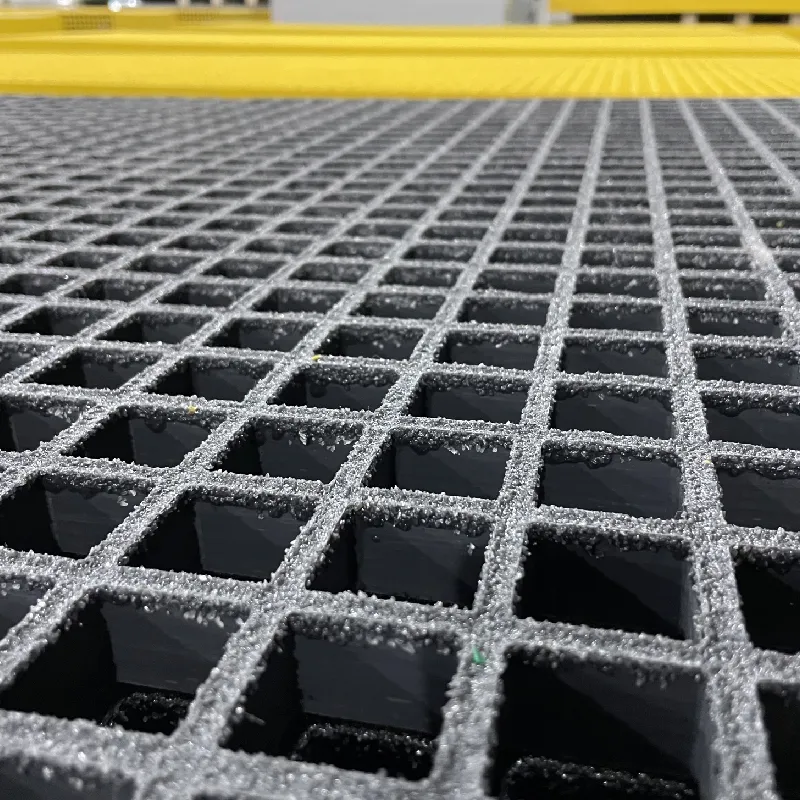

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025