loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

floor grating price

Understanding Floor Grating Prices Key Factors and Considerations

When it comes to industrial and commercial environments, floor grating plays a crucial role in ensuring safety, accessibility, and efficient drainage. It is a structural component used in various applications, from factories and warehouses to commercial kitchens and outdoor areas. However, before investing in floor grating, businesses often find themselves pondering the question what sets the price of floor grating? This article aims to delve into the main factors that influence floor grating prices and provide guidance for making informed purchasing decisions.

Types of Floor Grating

The first step in understanding floor grating prices is recognizing the different types available on the market. The most common materials used for floor grating are steel, aluminum, fiberglass reinforced plastic (FRP), and stainless steel. Each type has its unique properties, making them suitable for various applications

1. Steel Grating Generally heavier and more durable, steel grating is often used in industrial applications where high load-bearing capacity is required. However, it is susceptible to corrosion, making it essential to consider protective coatings, which can affect the price.

2. Aluminum Grating This type offers a lightweight solution with excellent corrosion resistance, ideal for environments where weight is a concern. Its price range tends to be slightly higher than that of steel but still affordable for many applications.

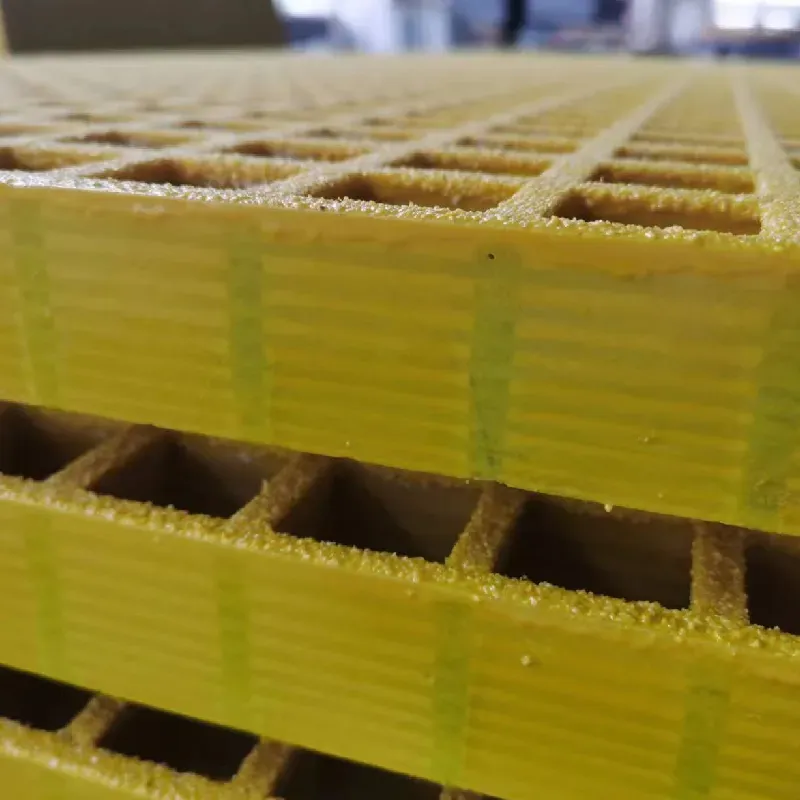

3. FRP Grating Known for its resistance to chemicals and UV light, FRP is a preferred choice in marine environments and chemical processing plants. The manufacturing process of FRP can make it more expensive than traditional metal gratings.

4. Stainless Steel Grating Renowned for its durability and resistance to corrosion and staining, stainless steel grating is often used in food processing and pharmaceuticals. It tends to be the most expensive option due to its premium properties.

Size and Load Capacity

Another critical factor influencing the price of floor grating is its size and load capacity. Grating comes in various dimensions, typically measured in terms of width, length, height, and spacing between bars. Larger and thicker gratings that can support heavier loads will naturally command higher prices due to the additional materials and manufacturing processes involved.

floor grating price

Customization and Design

Customization plays a significant role in floor grating pricing. Many businesses require gratings that meet specific design requirements, which might include unique sizes, shapes, or additional safety features (like slip-resistant surfaces). Manufacturers often charge a premium for custom-designed products, so it is vital to have a clear understanding of your needs before requesting quotes.

Quantity and Bulk Purchasing

Prices can vary significantly based on the quantity purchased. Many manufacturers offer discounts for bulk orders, which can lead to significant savings for businesses looking to purchase large quantities of grating. It's worth comparing unit prices between bulk and single-item purchases to ensure you're receiving the best deal.

Regional Differences

Geographical location can also impact floor grating prices. Different regions may experience varying costs due to shipping, local demand, and availability of materials. For instance, urban areas may see higher prices compared to more rural regions, where the demand for specialized gratings might be lower.

Installation Costs

Lastly, it is essential to factor in installation costs when considering floor grating prices. Depending on the complexity of the installation, this can add substantially to the overall project budget. Some businesses may opt to install the grating themselves, while others may require professional assistance, which can further vary costs.

Conclusion

In conclusion, understanding the various factors that influence floor grating prices—such as material type, size, customization, quantity, region, and installation costs—can help businesses make smarter purchasing decisions. By carefully evaluating these aspects, companies can choose the right floor grating solution that meets their operational needs while staying within budget. Investing time in research and comparison can lead to a more cost-effective and satisfactory outcome, ensuring safety and efficiency in the workplace.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025