loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

floor grating clamps

Understanding Floor Grating Clamps An Essential Component in Industrial Applications

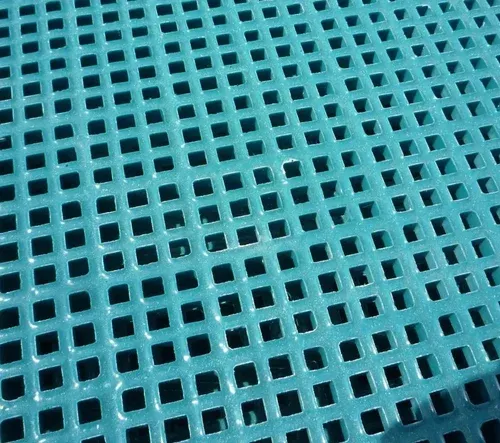

In various industrial settings, maintaining safety and efficiency is paramount. One critical component that plays a significant role in ensuring these standards is the floor grating clamp. Designed to secure floor grating panels, these clamps serve not only as a means of assembly but also enhance overall safety by preventing tripping hazards and providing a stable platform for workers.

What Are Floor Grating Clamps?

Floor grating clamps are hardware devices specifically engineered to hold grating materials firmly in place. They can be made from various materials, including stainless steel, aluminum, and mild steel, depending on the application and environmental conditions. The choice of material is crucial, as it affects the clamp’s resistance to corrosion, weight, and overall strength.

Typically, grating clamps come in different sizes and types to accommodate various grating patterns and thicknesses. Their design allows for quick installation and removal, making them a flexible solution for dynamic work environments.

Importance of Floor Grating Clamps

1. Enhanced Safety One of the primary purposes of floor grating clamps is to create a safe working environment. Loose grating can pose severe hazards, leading to slips, trips, and falls. By securing the grating, these clamps reduce the risk of accidents, thereby protecting workers and minimizing downtime.

2. Increased Durability Secured grating withstands the rigors of heavy foot traffic, machinery, and environmental factors. By using high-quality clamps, companies can prolong the life of their floor grating systems, resulting in cost savings on maintenance and replacements.

floor grating clamps

3. Cost-Effectiveness Investing in quality floor grating clamps may seem like a minor expense compared to the potential costs associated with workplace injuries and equipment failures. In the long run, these clamps contribute to a more efficient, safer, and productive workspace.

4. Versatility Floor grating clamps are versatile and can be used in various industries, including construction, manufacturing, oil and gas, and food processing. Their adaptability allows for use in diverse applications ranging from walkways and platforms to drainage systems.

Installation and Maintenance

Installing floor grating clamps is generally a straightforward process. It requires minimal tools, and maintenance is equally simple. Regular checks for wear and tear, especially in environments exposed to harsh chemicals or weather conditions, are recommended. Ensuring that the clamps are tightened properly maintains their effectiveness over time.

When it comes to choosing the right floor grating clamps, it’s essential to consider the specific requirements of your application. Factors such as load-bearing capacity, environmental exposure, and grating material will influence the type of clamp needed.

Conclusion

Floor grating clamps may appear to be a small component in the grand scheme of industrial operations, but their role is undeniably significant. They enhance safety, increase the durability of grating systems, and foster a cost-effective approach to workplace management. As industries continue to evolve, the need for reliable and efficient safety solutions like floor grating clamps will only grow. By prioritizing the installation and maintenance of these essential components, companies can ensure a safer, more productive environment for their workforce, ultimately leading to improved operational efficiency and success.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025