loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

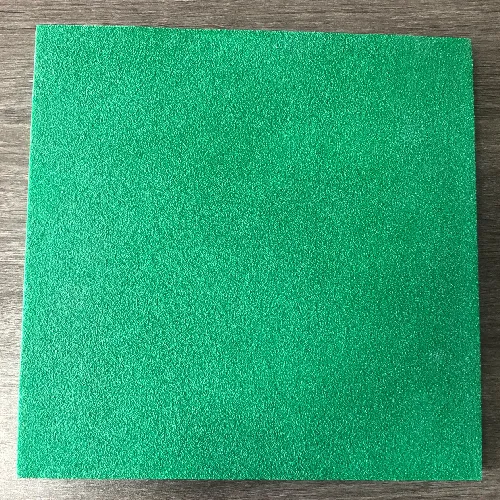

floor grating clamps

Understanding Floor Grating Clamps Essential Components for Safety and Stability

Floor grating clamps are crucial components in the construction and maintenance of industrial flooring systems, especially in areas where safety and durability are paramount. These clamps are specifically designed to secure grating panels, ensuring that they remain in place under various environmental conditions and loads.

The Importance of Floor Grating

Floor grating refers to the open spaces created in flooring systems, typically used in walkways, walkable ceilings, and industrial platforms. It allows for drainage, ventilation, and light penetration while providing a sturdy surface for foot traffic and machinery. The materials used for floor grating can vary from steel and aluminum to fiberglass, each offering unique advantages such as strength, corrosion resistance, and weight efficiency.

Role of Floor Grating Clamps

Given the diverse applications of floor grating, maintaining its structural integrity is vital. This is where floor grating clamps come into play. They serve several important functions

1. Securing Grating Panels Clamps firmly hold grating panels in place, preventing movement and ensuring that the surface remains stable. This is especially important in areas exposed to heavy machinery, where vibrations could loosen or displace the panels over time.

2. Enhancing Safety By keeping grating securely attached to the underlying structure, clamps reduce the risk of accidental slips and falls. Loose or shifting grates can lead to serious accidents, making reliable clamps an essential safety feature in any industrial environment.

3. Facilitating Easier Maintenance With well-secured grating, maintenance staff can perform inspections and maintenance on the underlying systems without the added concern of dislodged panels. This not only speeds up maintenance work but also enhances overall workplace safety.

floor grating clamps

Types of Floor Grating Clamps

There are various types of floor grating clamps available, each designed for specific grating materials and applications

. Some of the most common types include- Wing Clamps Featuring a simple screw mechanism, wing clamps allow for easy installation and removal, making them ideal for areas that require frequent access.

- Toggle Clamps These clamps utilize a toggle mechanism to provide a strong hold, often used in high-load applications.

- Adjustable Clamps These offer versatility in securing grating panels of different thicknesses or designs, ensuring a tight fit regardless of the specific requirements.

Considerations When Choosing Grating Clamps

When selecting floor grating clamps, several factors must be taken into account. The material of the clamp should correlate with the type of grating used in order to prevent corrosion and ensure long-lasting performance. Additionally, the environmental conditions—such as exposure to chemicals, temperature fluctuations, or heavy loads—should influence your choice.

Conclusion

Floor grating clamps may seem like small, simple components, but their role in ensuring the safety and functionality of industrial flooring systems cannot be underestimated. By securing grating panels, they provide stability, enhance safety, and facilitate maintenance. As such, choosing the right type of clamp is essential for any project involving floor grating, marking the difference between a reliable infrastructure and potential hazards. Investing in quality floor grating clamps is not just about compliance; it’s about ensuring safety and operational efficiency in the workplace.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025