loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

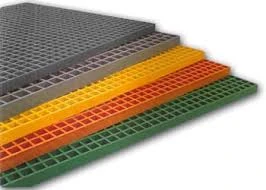

Floor Grating Clamp Solutions for Secure and Efficient Flooring Systems

Understanding Floor Grating Clamps Essential Components for Safety and Durability

Floor grating clamps are crucial components that play a pivotal role in ensuring the safety and durability of various flooring applications. Commonly used in industrial environments, these clamps secure grating panels in place, providing stability and support. This article delves into the importance of floor grating clamps, their types, applications, and the factors to consider when selecting the right clamps for specific needs.

The Importance of Floor Grating Clamps

In many industrial settings, such as manufacturing plants, warehouses, and chemical processing facilities, floor grating serves as a fundamental element for safe walking surfaces while allowing efficient drainage and ventilation. However, without appropriate fastening solutions, the integrity of these grates can be compromised, leading to potential hazards such as slips, trips, and falls.

Floor grating clamps ensure that grating panels are securely fastened to their supports, reducing the risk of movement or dislodgment. This is particularly vital in environments where heavy machinery operates or where personnel frequently traverse the area. By using clamps, facilities can enhance workplace safety, minimize maintenance costs, and prolong the lifespan of flooring systems.

Types of Floor Grating Clamps

There are several types of floor grating clamps available, each designed for specific applications and requirements

1. U-Clamps These are shaped like the letter U and are among the most common types of grating clamps. U-clamps are used primarily to secure rectangular grating panels to their load-bearing supports. They come in various sizes to accommodate different grating thicknesses.

2. L-Clamps Shaped like the letter L, these clamps are typically used in corners or tight spaces where standard U-clamps may not fit effectively. They provide additional support and stability, ensuring that grating panels remain securely attached even in challenging environments.

3. Top Grating Clamps These clamps are designed to hold grating panels from the top. They are often used in applications where excessive downward pressure may be exerted on the grates, such as in large machinery areas.

4. Specialized Clamps In some cases, custom clamps are needed for unique configurations or special materials. These clamps may be designed specifically for certain projects and can be tailored to meet the client’s exact specifications.

Applications of Floor Grating Clamps

Floor grating clamps are used in a diverse range of applications across different industries, including

floor grating clamps

- Industrial Facilities From manufacturing plants to power facilities, floor grating systems are essential for various industries, where clamps ensure safety and stability

.- Commercial Buildings In commercial settings, grating is often used in parking structures, walkways, and stairways, where clamps help secure the flooring and prevent hazards.

- Food and Beverage Industry Hygiene is crucial in food processing environments. Floor grating allows for easy drainage and cleaning, while clamps maintain the layout's integrity.

- Wastewater Treatment Plants Grating systems in these facilities are subjected to harsh conditions. Clamps are essential in ensuring that grates withstand these stresses.

Selecting the Right Floor Grating Clamps

When choosing floor grating clamps, several factors should be considered

1. Material The material of the clamp must be compatible with the grating and the environmental conditions. Stainless steel, for example, offers excellent corrosion resistance, making it suitable for outdoor or harsh environments.

2. Size and Dimensions It's essential to select clamps that fit the dimensions of the grating panels and support structures. Incorrect sizes can lead to ineffective fastening, which can compromise safety.

3. Load Requirements Understanding the load capacities involved is critical. Clamps must be able to handle the anticipated weight and pressure, especially in high-traffic or heavy equipment areas.

4. Installation Type Consideration should also be given to how the clamps will be installed. Some clamps require special tools or techniques, which could influence maintenance routines.

Conclusion

In summary, floor grating clamps are indispensable in maintaining the safety and reliability of various flooring systems across numerous industries. By understanding the types, applications, and selection criteria for these clamps, facility managers and engineers can ensure that their work environments remain safe and efficient. Investing in the right floor grating clamps is a proactive step toward minimizing risks and enhancing overall operational effectiveness.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025