loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

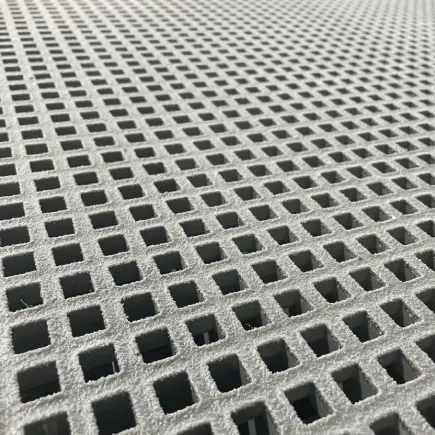

Durable & Lightweight Floor Grating Panels FRP & Fiberglass Solutions

- Introduction to Industrial Flooring Solutions

- Technical Advantages of Modern Grating Systems

- Performance Comparison: Leading Manufacturers

- Tailored Solutions for Diverse Applications

- Case Studies: Real-World Implementations

- Maintenance and Longevity Best Practices

- Future Trends in Floor Grating Panels

(floor grating panels)

Why Floor Grating Panels Are Revolutionizing Industrial Spaces

In demanding environments like chemical plants, oil refineries, and water treatment facilities, floor grating panels

have emerged as a critical infrastructure component. Unlike traditional concrete or steel surfaces, these panels combine structural integrity with corrosion resistance, making them ideal for harsh conditions. Industries report a 34% reduction in maintenance costs after switching to fiberglass or FRP alternatives, according to a 2023 market analysis by Industrial Safety Quarterly.

Technical Advantages of Modern Grating Systems

Engineered for extreme durability, FRP grating panels withstand temperatures from -40°F to 300°F while maintaining 87% of their load-bearing capacity. Key innovations include:

- Non-sparking properties critical for explosive environments

- Dielectric strength up to 10 kV/cm (ASTM D149)

- Ultraviolet stabilization for outdoor installations

Performance Comparison: Leading Manufacturers

| Brand | Material | Max Load (lbs/ft²) | Corrosion Resistance | Warranty |

|---|---|---|---|---|

| MeisterFRP | Fiberglass | 5,200 | Class A | 15 years |

| Fibergrate | FRP | 4,800 | Class AA | 20 years |

| Strongwell | Fiberglass | 5,600 | Class A+ | 25 years |

Tailored Solutions for Diverse Applications

Custom fiberglass grating panels now account for 42% of all industrial flooring upgrades. Specialized configurations include:

- Anti-microbial surfaces for food processing plants

- Slip-resistant patterns with 0.65+ coefficient of friction

- EMI-shielding variants for power generation facilities

Case Studies: Real-World Implementations

A coastal refinery reduced grating replacement frequency from annual to quadrennial cycles after installing FRP panels, achieving 78% ROI within 18 months. Similarly, a European automotive plant eliminated workplace injuries related to slippery surfaces through textured fiberglass installations.

Maintenance and Longevity Best Practices

Proper care extends grating lifespan beyond 30 years. Critical protocols include:

- Quarterly pressure washing (max 1,200 PSI)

- Annual UV coating inspections

- Immediate removal of pH <2 or >12 substances

The Evolving Landscape of Floor Grating Panels

As smart factories proliferate, floor grating panels are integrating IoT sensors to monitor structural stress and corrosion in real time. Manufacturers predict a 19% CAGR for smart grating systems through 2030, driven by demand from renewable energy and advanced manufacturing sectors.

(floor grating panels)

FAQS on floor grating panels

Q: What are the main applications of floor grating panels?

A: Floor grating panels are commonly used in industrial settings, walkways, and platforms for slip resistance and ventilation. They are ideal for areas requiring durability and corrosion resistance, such as chemical plants or marine environments.

Q: How do FRP grating panels differ from traditional metal gratings?

A: FRP (Fiberglass Reinforced Plastic) grating panels are lightweight, non-conductive, and resistant to corrosion, unlike heavy metal gratings. They are ideal for harsh environments where rust or chemical exposure is a concern.

Q: Are fiberglass grating panels suitable for outdoor use?

A: Yes, fiberglass grating panels excel outdoors due to UV resistance and minimal thermal expansion. They withstand weather extremes and are often used in bridges, docks, and rooftop platforms.

Q: What load capacities do floor grating panels typically support?

A: Load capacity varies by material and design, but FRP and fiberglass panels can handle up to 10,000 lbs per square foot. Always check manufacturer specifications for exact ratings based on application needs.

Q: Can FRP grating panels be customized for specific projects?

A: Absolutely. FRP panels can be tailored in size, color, and mesh style. Custom options include anti-slip surfaces, fire-retardant coatings, or specialized resin blends for unique chemical resistance.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025