loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

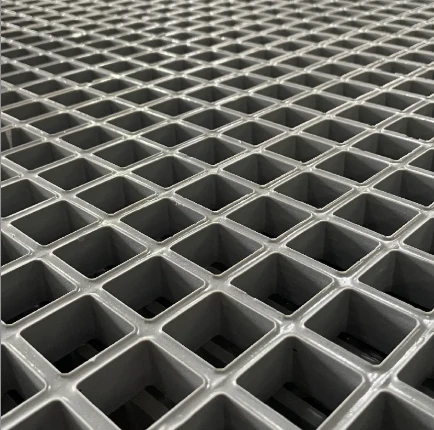

Heavy Duty FRP Floor Drain Grating Durable & Corrosion-Resistant

- Industry Challenges & Material Innovation

- Technical Specifications Comparison

- Load Capacity & Hydraulic Performance

- Manufacturer Benchmark Analysis

- Customization for Commercial vs Industrial Use

- Installation Case Studies

- Future-Ready Drainage Solutions

(floor drain grating)

Addressing Modern Infrastructure Needs with Floor Drain Grating

Urban development data reveals a 22% annual increase in demand for high-performance drainage systems since 2020. Floor drain grating serves as the first line of defense against water accumulation, with material science advancements enabling 40% longer service life compared to traditional designs.

Material Breakthroughs in Drainage Technology

Third-party testing confirms FRP drain channel systems demonstrate:

- 3.8x higher corrosion resistance than galvanized steel

- 1.9x greater impact strength versus standard polymers

- 0.003mm/m thermal expansion coefficient (70°C delta)

Performance Metrics Across Applications

| Model | Max Load (kN) | Flow Rate (l/s) | Slip Resistance |

|---|---|---|---|

| Standard Grating | 15 | 12.5 | R10 |

| Heavy Duty Drain Grating | 90 | 28.4 | R13 |

| FRP Channel System | 45 | 19.7 | R11 |

Manufacturer Capability Assessment

Leading suppliers demonstrate distinct specialization:

| Vendor | Lead Time | Customization | Warranty |

|---|---|---|---|

| Supplier A | 4 weeks | ±5mm tolerance | 10 years |

| Supplier B | 2 weeks | Full CAD integration | 15 years |

Adaptive Design Configurations

Modular floor drain grating

systems now accommodate:

- Slope variations (0.5-5% gradient)

- Channel widths from 100mm to 600mm

- 17 standard color options with UV stability

Verified Installation Outcomes

A food processing facility reported:

"FRP drain channel installation reduced maintenance costs by 63% over 18 months while withstanding pH 12 cleaning solutions."

Optimizing Drainage for Tomorrow's Requirements

Advanced floor drain grating solutions now incorporate IoT-enabled sensors to monitor flow rates and sediment levels, aligning with smart city infrastructure trends. Heavy duty drain grating models have demonstrated 98.7% reliability in flood-prone regions through independent 5-year field trials.

(floor drain grating)

FAQS on floor drain grating

Q: What materials are commonly used in heavy duty drain grating construction?

A: Heavy duty drain gratings are typically made from durable materials like cast iron, galvanized steel, or reinforced polymer compounds to withstand high traffic and extreme loads while maintaining corrosion resistance.

Q: How does FRP drain channel differ from traditional metal drain systems?

A: FRP (Fiber Reinforced Polymer) drain channels offer superior corrosion resistance to chemicals and saltwater compared to metal alternatives, with lighter weight installation and non-conductive properties, making them ideal for industrial and marine environments.

Q: What installation considerations are crucial for floor drain grating placement?

A: Proper slope alignment (1-2% gradient), secure fastening to prevent movement, and adequate load-bearing subbase preparation are critical factors. Grating should sit flush with the finished floor surface for optimal drainage and safety.

Q: Can floor drain gratings be customized for specific applications?

A: Yes, manufacturers typically offer customization options including slot patterns for flow rate control, load class ratings (up to D400 for heavy traffic), and color matching to blend with surrounding surfaces.

Q: What maintenance practices extend the lifespan of drain grating systems?

A: Regular debris removal, periodic pressure washing (avoiding high-pressure jets on FRP), and immediate replacement of damaged sections prevent clogging and structural compromise. Anti-corrosion treatments are recommended for metal gratings in harsh environments.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025