loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Advancements in Fiber-Reinforced Plastic Tanks and Vessels for Enhanced Durability and Performance

Fibre Reinforced Plastic Tanks and Vessels A Technological Leap in Storage Solutions

In recent years, the demand for innovative storage solutions has soared across various industries. One of the most significant advancements in this area has been the development of fibre reinforced plastic (FRP) tanks and vessels. FRP technology combines the robustness of traditional materials with the lightweight characteristics of plastics, resulting in a versatile and highly efficient solution for storing liquids and gases.

What is Fibre Reinforced Plastic?

Fibre reinforced plastic is a composite material made of a polymer matrix reinforced with fibres. The fibres, typically made of glass, carbon, or aramid, enhance the strength, stiffness, and overall durability of the plastic. This fusion of materials creates a lightweight yet strong structure that can withstand extreme pressures, temperatures, and corrosive environments.

Key Advantages of FRP Tanks and Vessels

1. Corrosion Resistance One of the standout features of FRP is its exceptional resistance to corrosion, making it an ideal choice for storing chemicals, water, and other corrosive substances. Unlike metal tanks that can rust and degrade over time, FRP maintains its integrity, reducing maintenance costs and increasing lifespan.

2. Lightweight Construction FRP tanks are significantly lighter than their metal counterparts, making them easier to transport and install. This lightweight characteristic also eases the burden on infrastructure, allowing for simpler support structures and reducing overall project costs.

3. Customizable Designs The moulding processes used in FRP production allow for high levels of customization. Tanks and vessels can be tailored to specific shapes, sizes, and colors, fitting seamlessly into diverse operational settings and meeting unique client needs.

4. Thermal Insulation FRP offers excellent thermal insulation properties, making it suitable for applications where temperature control is vital. This feature conserves energy and helps in maintaining the desired temperature of stored substances.

5. Longevity and Durability The lifespan of FRP tanks and vessels can reach several decades with proper maintenance. Their ability to withstand environmental stressors such as UV rays, moisture, and extreme weather conditions contributes to their long-term durability.

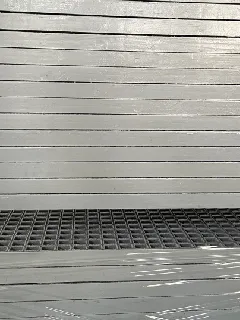

fibre reinforced plastic tanks and vessels

6. Environmental Sustainability As industries become more environmentally conscious, the use of FRP presents a sustainable option. Many manufacturers employ recyclable materials in their production processes, aligning with the increasing demand for eco-friendly solutions.

Applications of FRP Tanks and Vessels

The versatility of FRP makes it suitable for a wide range of applications across multiple industries

- Chemical Industry Due to their corrosion resistance, FRP tanks are widely used for storing acids, bases, and other hazardous chemicals without risk of leakage or degradation.

- Water Treatment FRP is utilized in water and wastewater treatment facilities, including storage tanks and chemical dosing systems, to ensure reliable and safe operations.

- Food and Beverage With stringent regulations in place for food safety, FRP vessels can be employed in the dairy and beverage industries for fermentation, storage, and processing, offering a hygienic solution.

- Oil and Gas FRP tanks and vessels find application in the oil and gas sector for storing fuels and hazardous materials, where robustness and safety are paramount.

Conclusion

Fibre reinforced plastic tanks and vessels represent a significant technological advancement in storage solutions. Their corrosion resistance, lightweight nature, and durability make them an attractive choice for various industries, from chemicals to food processing. As businesses seek to enhance efficiency while adhering to sustainability goals, the adoption of FRP technology is likely to grow, showcasing its potential to reshape storage solutions for the future. With continuous innovations in materials science, FRP tanks and vessels will undoubtedly play a crucial role in meeting the demands of modern industry.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025