loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

fibre reinforced plastic tanks

Fibre Reinforced Plastic Tanks An Overview

Fibre reinforced plastic (FRP) tanks have gained significant traction in various industries due to their durability, lightweight nature, and resistance to corrosion. These tanks are primarily composed of a polymer matrix reinforced with fibrous materials, such as glass or carbon fibres. The combination of these materials imparts unique properties, making FRP tanks ideal for storing a multitude of liquids across different applications.

Advantages of Fibre Reinforced Plastic Tanks

One of the most notable advantages of FRP tanks is their remarkable resistance to corrosion. Unlike traditional materials such as steel or concrete, which can succumb to rust and degradation when exposed to aggressive chemicals, FRP tanks remain intact and functional over extended periods. This resilience is particularly beneficial in industries such as chemical processing, wastewater treatment, and petrochemicals, where stored substances may contain corrosive agents.

Another benefit is their lightweight design. This characteristic simplifies transportation and installation, especially in remote locations where heavy lifting equipment may not be readily available. The ease of handling associated with FRP tanks not only reduces labor costs but also minimizes the risk of workplace accidents that can occur with the movement of heavier materials.

In addition to their physical attributes, FRP tanks also offer excellent thermal insulation and reduced energy costs. Their ability to maintain temperature makes them suitable for storing temperature-sensitive liquids, thereby preserving the quality of the contents.

Applications of FRP Tanks

FRP tanks have a wide array of applications across different sectors. In the water treatment industry, these tanks are commonly used for the storage of potable water, as well as in the containment of chemicals used in treatment processes. Their anti-corrosive properties ensure that the water quality remains uncompromised.

The oil and gas sector relies heavily on FRP tanks for storing various fuels and chemicals. These tanks offer safety and longevity amid challenging environmental conditions, such as extreme temperatures or harsh weather phenomena. Their designs often comply with industry regulations, ensuring safe storage practices.

Moreover, FRP tanks are frequently employed in the agricultural sector for the storage of fertilizers and pesticide solutions. The inert nature of the materials used in their construction means that there is minimal risk of contamination, which is a crucial aspect for farmers and agricultural businesses.

fibre reinforced plastic tanks

Environmental Considerations

Sustainability is a critical aspect of modern manufacturing, and FRP tanks offer several eco-friendly advantages. The longevity of these tanks means they require less frequent replacement than traditional materials, reducing waste and consumption of resources over time. Moreover, many manufacturers are beginning to incorporate recycled fibres in the production of FRP, further enhancing their sustainability credentials.

Additionally, the manufacturing process of FRP tanks typically generates fewer pollutants compared to the production of conventional materials. With growing concerns about environmental impact, the adoption of FRP technology aligns with the goals of organizations aiming for greener operations.

Challenges and Future Prospects

Despite their numerous advantages, FRP tanks are not without challenges. The initial cost of production can be higher than that of traditional materials, which may deter some businesses from transitioning to FRP technology. However, the long-term savings and durability often justify this upfront investment.

Furthermore, while advancements in manufacturing techniques are making FRP tanks more accessible, continuous research is necessary to further enhance their mechanical properties and expand their application to even more aggressive environments.

Manufacturers are exploring composite materials and innovative designs to improve the performance of FRP tanks. The future of this technology looks promising, with potential developments poised to address current limitations while enhancing overall efficiency.

Conclusion

Fibre reinforced plastic tanks represent a significant advancement in storage solutions across many industries. Their unique combination of resistance to corrosion, lightweight design, and versatility makes them a preferred choice for various applications. As industries continue to prioritize sustainability and operational efficiency, the adoption of FRP technologies will likely increase. By overcoming current challenges and investing in research and development, the future of FRP tanks looks bright, paving the way for more innovative and environmentally friendly storage solutions.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

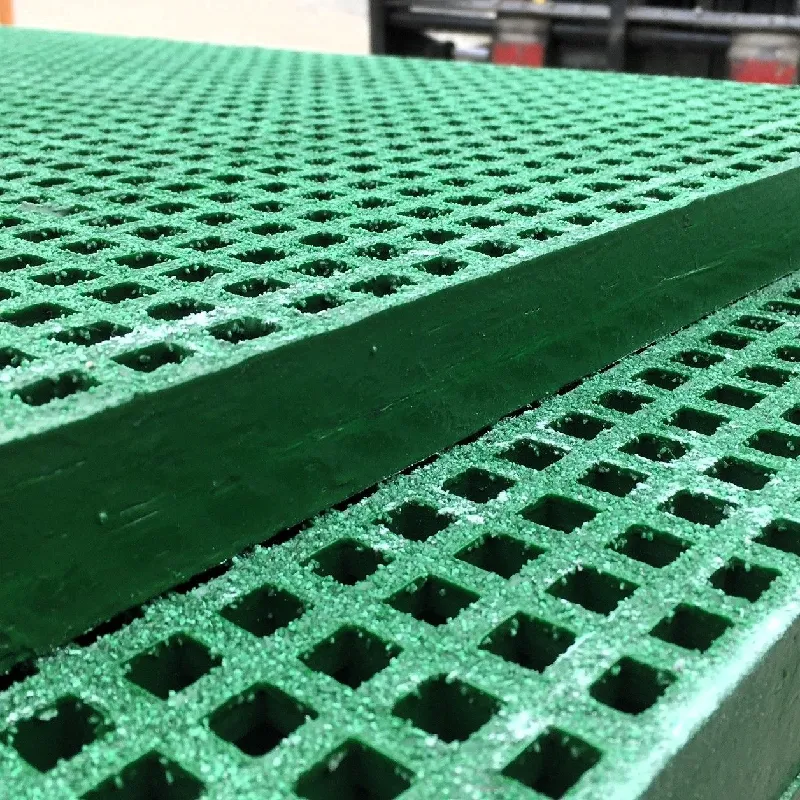

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025