loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

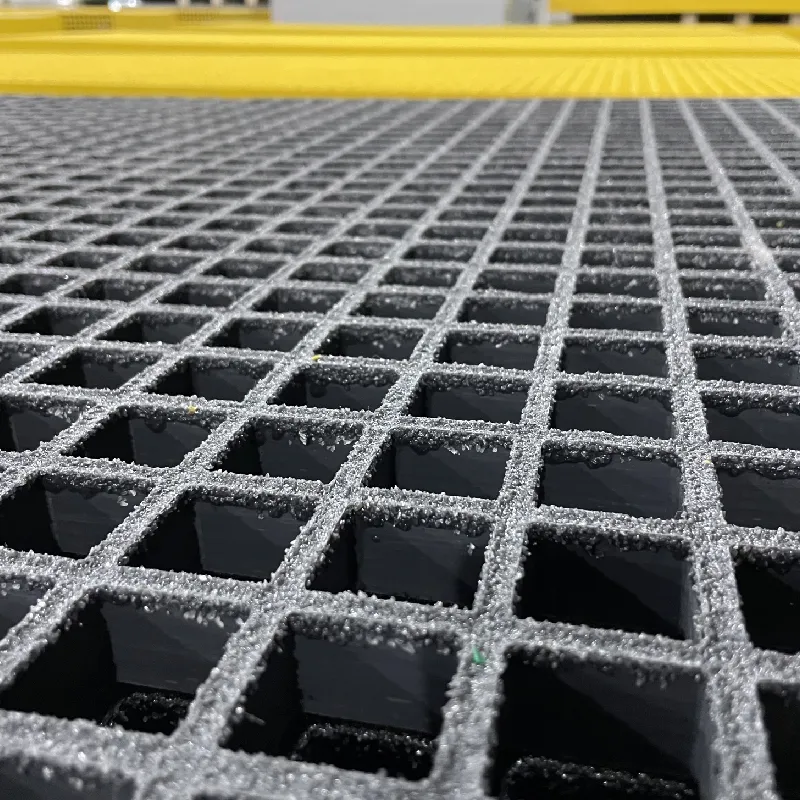

fibre reinforced plastic grating

The Advantages of Fibre Reinforced Plastic Grating

Fibre Reinforced Plastic (FRP) grating is an innovative material that has gained significant popularity across various industries over recent years. This unique combination of glass or carbon fibers with resin creates a lightweight yet incredibly strong product. As industries continue to prioritize safety, durability, and cost-effectiveness, FRP grating is emerging as a leading alternative to traditional materials such as steel and wood. This article will explore the advantages of FRP grating and its applications, shedding light on why it is becoming a staple in modern construction and industrial processes.

1. High Strength-to-Weight Ratio

One of the most notable benefits of FRP grating is its high strength-to-weight ratio. The fibers in FRP provide substantial strength without adding significant weight. This characteristic is especially advantageous for construction projects where reducing the load on support structures is crucial. The lightweight nature of FRP grating allows for easier installation, often requiring less manpower and equipment, which translates to lower labor costs and reduced project timelines.

2. Corrosion Resistance

FRP grating is inherently resistant to corrosion and chemical damage. Unlike traditional materials such as steel, which can rust and degrade when exposed to moisture and chemicals, FRP grating maintains its integrity in harsh environments. This makes it an ideal choice for applications in chemical processing plants, wastewater treatment facilities, and coastal areas where saltwater exposure is a concern. The longevity of FRP grating reduces the need for frequent replacements, thereby offering long-term cost savings.

3. Safety Features

Safety is a paramount consideration in industrial settings. FRP grating comes with excellent slip-resistant properties, making it an ideal flooring option for walkways, platforms, and stairs. The surface can be tailored to enhance grip, reducing the chances of slips and falls. Additionally, because FRP grating does not conduct electricity, it is a safer alternative in electrical environments where shock hazards are a concern.

4. Low Maintenance

fibre reinforced plastic grating

Another significant advantage of FRP grating is its low maintenance requirement. Traditional materials often necessitate regular upkeep to prevent deterioration. However, FRP grating is easy to clean, and its resilience against chemicals means that it does not require special treatments or coatings to maintain its appearance and function. This feature not only saves time for facility management but also cuts down on maintenance costs.

5. Versatility and Customization

FRP grating is versatile and can be customized to meet specific project needs. It is available in a variety of colors, patterns, and sizes, allowing for tailored solutions that fit differing aesthetic and functional requirements. Whether it's for decorative purposes in architectural designs or for functional use in industrial settings, FRP grating can be molded and manufactured to achieve the desired specifications.

6. Environmental Considerations

As industries strive for greater sustainability, FRP grating emerges as an environmentally friendly option. The production process of FRP can be optimized to minimize waste, and its long lifespan reduces the frequency of replacements contributing to less landfill waste. Furthermore, many manufacturers are now offering recycled FRP options, further reducing the environmental footprint.

7. Cost-Effectiveness

While the initial investment in FRP grating might be higher than that of traditional materials, the long-term cost-effectiveness is evident. The combination of low maintenance, high durability, and reduced installation labor costs make FRP grating a wise choice for many projects. Moreover, its resistance to wear and tear means that businesses will not face frequent expenses related to repairs and replacements.

Conclusion

Fibre Reinforced Plastic grating stands out as a superior material in various industrial and construction applications. Its remarkable strength-to-weight ratio, corrosion resistance, safety features, low maintenance needs, versatility, and cost-effectiveness make it an attractive solution for many sectors. As industries continue to evolve and seek materials that offer durability and sustainability, FRP grating is poised to play an essential role in shaping the future of construction and industrial design. Embracing this advanced material may very well be a step toward a safer and more efficient working environment.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025