loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

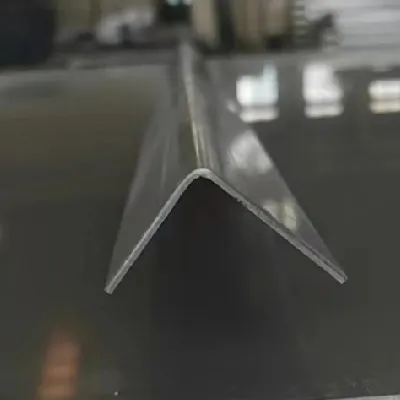

fibreglass reinforcement bar

The Advantages of Fiberglass Reinforcement Bars in Construction

In the ever-evolving construction industry, the demand for innovative materials that provide strength, durability, and sustainability is at an all-time high. One such product that has garnered attention is the fiberglass reinforcement bar, often referred to as GFRP (Glass Fiber Reinforced Polymer) rebar. This material presents a host of advantages that are reshaping the way we approach construction projects.

What is Fiberglass Reinforcement Bar?

Fiberglass reinforcement bars are composite materials made from a plastic matrix reinforced with glass fibers. Unlike traditional steel rebar, GFRP rebar is non-corrosive, lightweight, and possesses a high tensile strength, making it a favorable alternative in many construction applications. These attributes make fiberglass rebar particularly suitable for environments that challenge traditional materials, such as coastal and industrial areas.

Corrosion Resistance

One of the most significant advantages of fiberglass rebar is its resistance to corrosion. Steel reinforcement bars are prone to rust when exposed to moisture and chemical elements, leading to structural integrity issues over time. This is particularly problematic in areas exposed to saltwater or de-icing agents, where the cost of maintenance and repairs can skyrocket. Fiberglass rebar, however, does not corrode, which translates into lower lifecycle costs and reduced need for maintenance. Consequently, structures reinforced with GFRP can offer enhanced longevity and safety.

Lightweight and Easy to Handle

The light weight of fiberglass reinforcement bars is another compelling advantage. GFRP rebar is approximately 70% lighter than its steel counterpart. This property not only makes handling and installation easier but also leads to lower transportation costs. Construction teams can manage materials without heavy lifting equipment, thereby reducing labor costs and increasing efficiency. The reduced weight can also lead to cost savings in the overall structural design, allowing for lighter concrete slabs and reduced foundation requirements.

fibreglass reinforcement bar

High Tensile Strength

Fiberglass reinforcement bars possess a remarkable tensile strength, often exceeding that of traditional steel rebar. This feature enables architects and engineers to design structures that can withstand significant forces while using less material. The high strength-to-weight ratio of GFRP rebar allows for innovative architectural designs that were previously unattainable with conventional materials, promoting creativity and aesthetic appeal in construction.

Thermal Insulation Properties

Another advantage of fiberglass rebar is its thermal insulation properties. Unlike steel, which conducts heat, GFRP does not act as a thermal bridge, thus improving the energy efficiency of buildings. This characteristic can contribute to lower energy costs associated with heating and cooling in buildings, making fiberglass rebar an eco-friendly choice in sustainable architecture.

Environmental Considerations

As the construction industry strives for more sustainable practices, materials like fiberglass rebar stand out for their reduced environmental impact. The production of GFRP involves fewer resources, and because it has a longer lifespan while being recyclable, it addresses some critical concerns related to waste and resource depletion in construction.

Conclusion

The use of fiberglass reinforcement bars presents a myriad of advantages that are revolutionizing construction practices. With their corrosion resistance, lightweight nature, high tensile strength, thermal insulation properties, and environmental benefits, GFRP rebar is quickly becoming a preferred choice for engineers and architects looking to innovate and improve the durability and sustainability of their projects. As the industry continues to advance, materials like fiberglass rebar showcase the potential for a future where construction promotes efficiency, safety, and environmental responsibility.

-

Premium FRP Handrail for All ApplicationsNewsAug.29,2025

-

Low Maintenance FRP Mini Mesh Grating ProductsNewsAug.29,2025

-

Innovative FRP Square Tubes for Modern Industrial SolutionsNewsAug.29,2025

-

FRP Water Storage Tanks Wholesale Solutions for Bulk BuyersNewsAug.29,2025

-

FRP Molded Grating Solutions for Diverse Industrial ApplicationsNewsAug.29,2025

-

Construction Advancements Through FRP Pultruded ProfilesNewsAug.29,2025

-

Why Choose FRP Railings, Guardrails, and Handrail Systems?NewsAug.29,2025