loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

fibreglass reinforcement bar

The Rise of Fiberglass Reinforcement Bars in Construction

In recent years, the construction industry has witnessed a remarkable shift towards innovative materials that enhance the durability and sustainability of structures. One such innovation is the fiberglass reinforcement bar, commonly known as the fiberglass rebar (GFRP). This article explores the benefits, applications, and future prospects of fiberglass reinforcement bars, setting the stage for a new era in construction materials.

What is Fiberglass Rebar?

Fiberglass rebar is a composite material made from a combination of glass fibers and resin, offering a lightweight yet incredibly strong alternative to traditional steel reinforcement bars. Unlike steel, which is prone to corrosion, fiberglass bars are resistant to various environmental factors, making them ideal for use in diverse construction projects, particularly in harsher climates.

Advantages of Fiberglass Rebar

One of the primary advantages of fiberglass rebar is its outstanding corrosion resistance. This property significantly enhances the lifespan and durability of structures, particularly in areas with high humidity, salt exposure, or chemical pollutants. For instance, buildings near coastal areas or infrastructures like bridges over saltwater are particularly susceptible to steel corrosion. Fiberglass bars mitigate these risks, reducing maintenance costs and extending the service life of concrete structures.

Another significant benefit is weight. Fiberglass rebar is approximately one-fourth the weight of steel rebar, making it easier to handle and transport. This reduction in weight often translates to lower shipping costs and simplified on-site installation, allowing workers to focus on building efficiently rather than managing cumbersome materials.

Moreover, fiberglass rebar has a higher tensile strength compared to steel. This attribute allows for greater design flexibility and the ability to accommodate more substantial loads, making it a preferred choice among engineers searching for cost-effective and robust building solutions. Additionally, the non-conductive nature of fiberglass means that electrical fields do not disrupt its structural integrity, making it suitable for specific applications that require electromagnetic neutrality, such as in nuclear and telecommunications facilities.

fibreglass reinforcement bar

Applications in Various Industries

Fiberglass reinforcement bars have found applications across a wide range of sectors. In the civil engineering domain, they are particularly valuable for constructing highways and bridges, which are often exposed to corrosive environments. Many municipalities have adopted fiberglass rebar for their stormwater management systems, due to its durability and resistance to harsh chemicals found in runoff.

Moreover, the industrial sector has benefited from fiberglass rebar in the creation of chemical storage tanks and containment areas, where resistance to chemicals is paramount. The use of fiberglass in residential construction is also on the rise, particularly for basements and foundations, where moisture presence often compromises traditional reinforcement systems.

Sustainability and Future Prospects

As the world increasingly emphasizes sustainability in construction, fiberglass rebar has emerged as a promising alternative to traditional materials. Its durability leads to a longer lifespan for structures, which aligns with modern sustainability goals. Furthermore, many fiberglass products can be made from recycled materials, contributing to a more circular economy in construction practices.

The future of fiberglass reinforcement bars appears bright. Ongoing research and development are likely to enhance their properties further, leading to even more widespread adoption in various construction applications. As builders and architects explore innovative designs and solutions, fiberglass rebar may become a standard feature in the quest for resilience and efficiency in construction.

Conclusion

In summary, fiberglass reinforcement bars represent a significant advancement in construction technology. Their corrosion resistance, lightweight nature, and superior tensile strength position them as a preferred choice for modern building practices. As the construction industry continues to evolve, embracing sustainability and innovation, fiberglass rebar is poised to play a crucial role in creating more durable, reliable, and environmentally friendly structures for the future. The rise of fiberglass rebar is not just a trend; it signifies a paradigm shift towards smarter, more sustainable construction methodologies.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

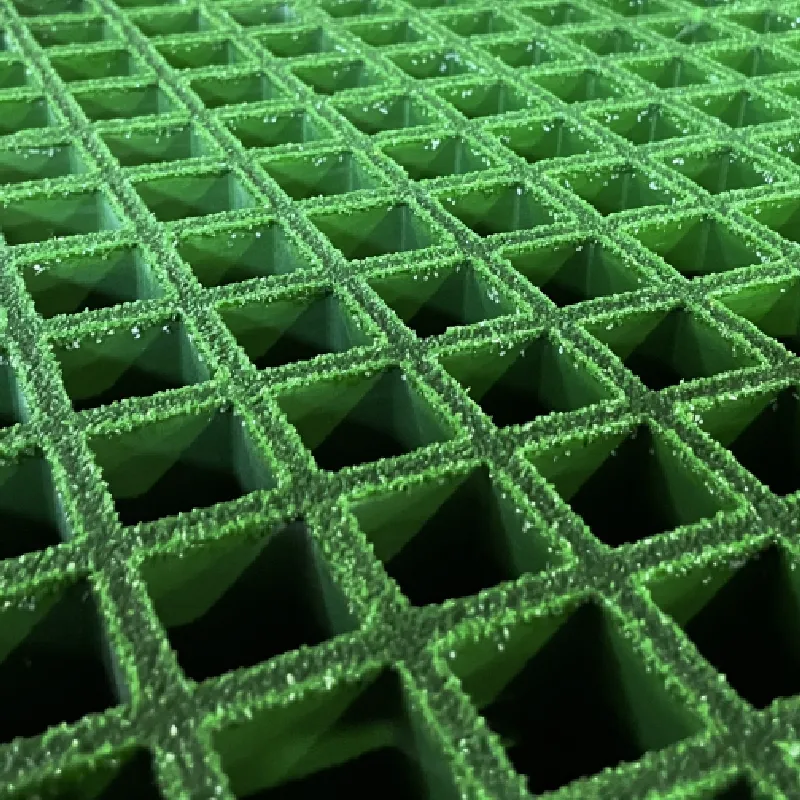

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025