loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

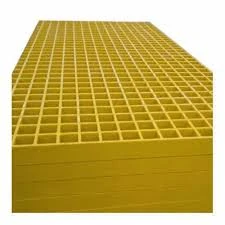

fibreglass reinforced plastic grating

Fibreglass Reinforced Plastic Grating An Overview

Fibreglass Reinforced Plastic Grating, commonly known as FRP grating, is a versatile and robust material that has gained popularity across various industries. Its unique combination of materials provides numerous advantages over traditional materials such as steel and wood, making it an excellent choice for a wide range of applications.

What is FRP Grating?

FRP grating consists of a fiberglass-reinforced polymer matrix, which is manufactured by combining glass fibers with a thermosetting resin. This composite material is formed into a grid-like structure that allows for lightweight yet strong support. The grating can be produced in various shapes and sizes to accommodate specific needs. It typically features a nonslip surface, enhancing safety in environments prone to spills or slippery conditions.

Advantages of FRP Grating

1. Corrosion Resistance One of the standout features of FRP grating is its resistance to corrosion. Unlike metal grating, FRP does not rust or degrade when exposed to harsh chemicals or salty environments, making it ideal for marine applications, chemical plants, and waste treatment facilities.

2. Lightweight FRP grating is significantly lighter than steel, making it easier to handle and install. This reduces labor costs and the need for heavy equipment during installation. The lightweight nature does not compromise its strength, making it suitable for heavy-duty applications.

3. Durability The inherent properties of FRP result in a high level of durability. It can withstand heavy loads, impact, and extreme temperatures, therefore, it finds applications in areas where traditional materials might fail.

4. Low Maintenance FRP grating requires minimal maintenance over its lifecycle compared to steel grating, which often needs regular painting to prevent rust and corrosion. This translates to lower operational costs and less downtime.

5. Safety Features Many FRP gratings come with a textured surface that provides excellent slip resistance, making them an ideal choice for walkways, platforms, and other areas where safety is a concern. This is particularly important in industrial settings where spills may occur frequently.

fibreglass reinforced plastic grating

6. Versatility FRP grating is available in a variety of sizes, shapes, thicknesses, and colors, providing flexibility for various applications. It can be used in flooring, platforms, stair treads, and even as coverings for industrial trenches.

Applications of FRP Grating

The applications of FRP grating extend across numerous sectors

.- Marine and Coastal Environments It is widely used in boat docks, piers, and bridges where exposure to seawater is common. The corrosion resistance ensures a long lifespan even in the most challenging environments.

- Chemical Plants Given its resistance to corrosive chemicals, FRP grating is used for walkways, platforms, and drainage cover in chemical manufacturing facilities.

- Wastewater Treatment In water treatment plants, FRP grating is utilized in various capacities, including platforms for equipment and floors in treatment facilities, offering safety and durability.

- Food Processing The non-porous surface and resistance to chemicals make it a suitable material for food processing environments, helping to maintain hygiene standards.

- Sports Facilities Many sports facilities use FRP grating for drainage systems due to its robust nature and lightweight characteristics.

Conclusion

In an era where the demand for efficient, durable, and safe materials is ever-increasing, fibreglass reinforced plastic grating stands out as an exemplary choice. Its ability to resist corrosion, lightweight nature, minimal maintenance needs, and versatility have established it as an invaluable asset across various industries. As technological advancements continue to improve the properties of FRP, its applications are likely to expand even further, cementing its place in modern material solutions. Adopting FRP grating means investing in longevity and safety, thereby enhancing operational efficiency in diverse applications.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025