loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

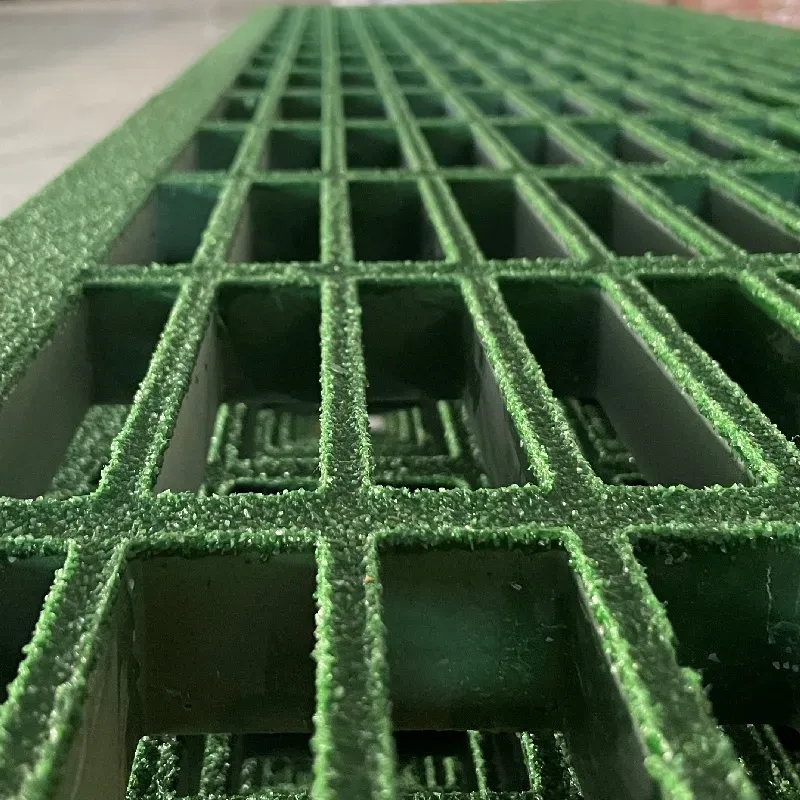

Versatile Applications of Fiberglass Reinforced Plastic Grating in Modern Industries

Fibreglass Reinforced Plastic Grating A Comprehensive Overview

Fibreglass reinforced plastic (FRP) grating is an innovative composite material gaining popularity across various industries due to its exceptional properties. Combining the strength of fiberglass with the versatility of plastic, FRP grating offers a multitude of benefits, making it an ideal choice for environments that demand durability, corrosion resistance, and lightweight construction.

What is FRP Grating?

FRP grating is manufactured by reinforcing plastic with fiberglass strands to enhance its mechanical properties. This combination results in a material that is not only lightweight but also possesses remarkable strength and structural integrity. The manufacturing process typically involves pultrusion, where fibers are drawn through a resin bath and cured to form rigid composite shapes.

Benefits of FRP Grating

1. Corrosion Resistance One of the primary advantages of FRP grating is its exceptional resistance to corrosive environments. Unlike traditional materials such as steel, FRP does not rust or corrode when exposed to harsh chemicals or moisture, making it ideal for use in chemical plants, sewage treatment facilities, and marine applications.

2. Lightweight and Easy to Install FRP grating is significantly lighter than steel and concrete alternatives, which simplifies handling and installation. This lightweight nature reduces labor costs and enables quicker project completion. Moreover, installation often requires fewer heavy tools and equipment, further facilitating the process.

3. Non-Slip Surface Safety is a critical consideration in facilities where grating is used. FRP grating is designed with a non-slip surface that ensures better footing, even in wet or oily conditions. This feature makes FRP an excellent choice for walkways, platforms, and stair treads in industrial settings.

4. Electrical Insulation Fibreglass naturally possesses non-conductive properties, making FRP grating an ideal solution for electrical applications. It safeguards against electric shocks and minimizes hazards in environments where electrical equipment is present.

5. UV Resistance Many FRP gratings are designed to withstand ultraviolet (UV) radiation. This resistance helps prevent degradation or color fading, ensuring that the grating maintains its appearance and structural integrity over time.

fibreglass reinforced plastic grating

6. Customizable and Versatile FRP grating can be customized in various sizes, shapes, and colors to fit specific project requirements. This versatility makes it suitable for a wide range of applications, from industrial flooring to architectural features.

Applications of FRP Grating

The versatility of FRP grating lends itself to numerous applications across different industries

- Chemical and Petrochemical Plants Due to its excellent resistance to corrosive substances, FRP grating is extensively used in chemical manufacturing facilities, refineries, and gas plants. It provides a safe and reliable surface for walkways, platforms, and drainage systems.

- Wastewater Treatment In wastewater treatment plants, FRP grating benefits from its ability to withstand harsh chemicals and moisture. Its non-slip surface also enhances safety for workers in these challenging environments.

- Food Processing The non-corrosive and non-toxic nature of FRP grating makes it suitable for the food and beverage industry, where sanitary conditions are paramount. It is easy to clean and resistant to mold and bacterial growth.

- Marine and Coastal Structures The marine environment is particularly harsh, with high levels of saltwater and UV exposure. FRP grating is a preferred choice for docks, piers, and other marine applications due to its resistance to corrosion and deterioration.

Conclusion

Fibreglass reinforced plastic grating stands out as a technologically advanced solution that meets the demands of modern industries. Its durability, lightweight construction, and resistance to corrosive elements position it as a superior alternative to traditional materials in various applications. As industries continue to prioritize safety, efficiency, and sustainability, the adoption of FRP grating is likely to grow, making it an essential material for the future. Whether for industrial, commercial, or environmental uses, FRP grating offers a robust and versatile option that can adapt to a wide array of needs.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025