loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Cost Analysis of Fiberglass Grating Products and Their Applications in Various Industries

The Price of Fiberglass Grating A Comprehensive Overview

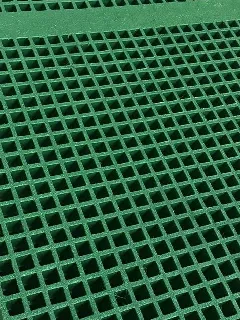

Fiberglass grating has become a popular choice across various industries due to its lightweight, corrosion-resistant, and durable characteristics. Used in a plethora of applications—from industrial flooring to walkways and drainage covers—the demand for fiberglass grating continues to rise. However, potential buyers often find themselves questioning the price of fiberglass grating. Understanding the factors that contribute to its cost can help consumers make informed decisions.

Understanding Fiberglass Grating

Fiberglass grating is an engineered product made from fiberglass reinforced plastic (FRP). Its primary components are glass filaments, resin, and fillers that provide strength and chemical resistance. The grating is manufactured using two main methods open molded and pultruded processes. Open molded grating is typically less expensive but offers less strength compared to pultruded grating, which is built layer by layer, ensuring enhanced durability and load-bearing capabilities.

Factors Influencing Price

Several factors contribute to the pricing of fiberglass grating

1. Type of Grating As mentioned, there are primarily two types molded and pultruded. Typically, pultruded grating comes with a higher price tag due to its strength and durability, making it suitable for more demanding applications.

2. Thickness and Size The dimensions of the grating significantly affect the cost. Thicker and larger panels require more raw materials, hence increasing the price. On average, standard sizes range from 1 foot by 1 foot to 4 feet by 12 feet, but custom sizes can be produced at an additional cost.

3. Load-Bearing Capacity Fiberglass grating can be designed to support varying weight loads, which impacts the price. Higher load-bearing capacities typically require thicker profiles and more robust materials, leading to increased costs.

fibreglass grating price

4. Surface Finish The surface finish of fiberglass grating can also impact pricing. For instance, anti-slip finishes provide added safety but can be more expensive than smooth finishes. Additionally, UV-resistant coatings may also increase the overall cost.

5. Market Conditions Like many manufacturing products, the price of fiberglass grating is influenced by market conditions, including supply chain issues, the availability of raw materials, and fluctuations in demand. During periods of high demand or supply shortages, prices may rise.

6. Manufacturer Different manufacturers may offer competitive pricing based on their production methods, overhead costs, and profit margins. Therefore, it is beneficial to obtain quotes from multiple suppliers.

Average Price Range

On average, the price of fiberglass grating can range between $20 to $100 per square foot, depending on the factors mentioned previously. Molded grating typically ranges from $20 to $40 per square foot, while pultruded grating can range from $40 to $100 or more. Custom solutions may further inflate the cost, but investing in quality grating ensures longevity and reduces replacement costs in the long run.

Cost-Benefit Analysis

When evaluating the price of fiberglass grating, it is essential to conduct a cost-benefit analysis. Though the initial upfront cost may be higher than traditional materials like steel or wood, the long-term savings in maintenance, replacement, and safety can make fiberglass a more economical choice. Furthermore, its resistance to corrosion, chemicals, and extreme weather conditions means it can outperform many alternatives in demanding environments.

Conclusion

The price of fiberglass grating is influenced by various factors, including its type, size, load-bearing capacity, and manufacturer. While it may seem costly upfront, its durability and low maintenance requirements often justify the investment. When considering fiberglass grating, it is crucial to assess both immediate and long-term costs while selecting a reputable supplier to ensure quality and performance. Ultimately, fiberglass grating remains a smart choice for many applications across different industries, providing both functionality and value for years to come.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025