loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Cost Analysis of Fiberglass Grating Options for Various Applications and Projects

Understanding Fibreglass Grating Prices Factors and Insights

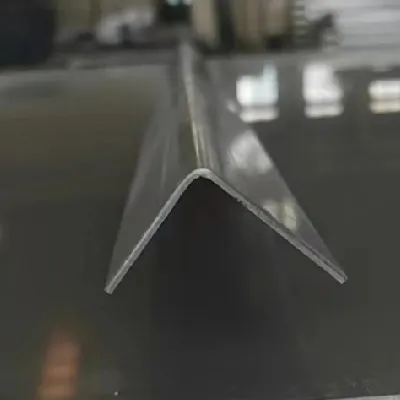

Fibreglass grating, also known as fiberglass reinforced plastic (FRP) grating, has gained immense popularity in various industries due to its durability, resistance to corrosion, and lightweight properties. As organizations seek cost-effective yet reliable material solutions, understanding the pricing of fibreglass grating becomes crucial. This article delves into the factors influencing the price of fibreglass grating and offers insights for potential buyers.

Factors Influencing Fibreglass Grating Prices

1. Material Composition The primary factor affecting the price of fibreglass grating is the quality and type of raw materials used. Higher-grade resin and fiberglass content typically lead to increased durability and strength, which can result in a higher price. Different types of resins, such as polyester and vinyl ester, also come with varying costs, affecting the final pricing.

2. Manufacturing Processes The production techniques employed also play a significant role in determining the cost. Advanced manufacturing methods that enhance the mechanical properties and lifespan of the grating, such as pultrusion and hand lay-up, may lead to higher prices due to the sophistication and energy required in the processes involved.

3. Dimensions and Customization Fibreglass grating is available in various sizes, thicknesses, and types (such as molded and pultruded). Customized solutions tailored to specific applications can significantly increase the costs. For instance, custom sizes or additional features like anti-slip surfaces may attract an additional fee, reflecting the extra work involved in production.

fibreglass grating price

4. Quantity and Bulk Pricing Like many materials, purchasing fibreglass grating in bulk can lead to cost savings. Suppliers often provide discounts for large orders, making it advantageous for businesses with extensive needs. Conversely, smaller orders may incur higher per-unit prices due to increased shipping and handling costs.

5. Supplier and Brand The reputation of the supplier can also impact pricing. Well-established manufacturers with a track record of quality might charge a premium for their products, while lesser-known brands may offer lower prices to attract customers. However, opting for cheaper options might compromise quality and durability, leading to higher long-term costs.

6. Market Demand and Competition The dynamics of supply and demand in the market also affect pricing. In periods of high demand, prices may increase, whereas competitive markets can drive prices down. Keeping an eye on market trends can be beneficial for businesses looking to purchase fibreglass grating at optimal prices.

Conclusion

When considering fibreglass grating, understanding the factors influencing its price is essential for making informed purchasing decisions. Businesses should evaluate their specific needs, including required durability, size, and customization options, to find the best solution within their budget. Additionally, it may be advantageous to compare quotes from various suppliers to ensure competitive pricing while maintaining quality.

Investing in quality fibreglass grating can lead to significant long-term savings by reducing maintenance costs and enhancing workplace safety. By taking the time to analyze the various components that contribute to pricing, buyers can make strategic decisions that align with their operational needs and financial constraints. Thus, navigating the landscape of fibreglass grating prices can help organizations procure materials that not only meet their immediate needs but also support their long-term goals.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025