loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

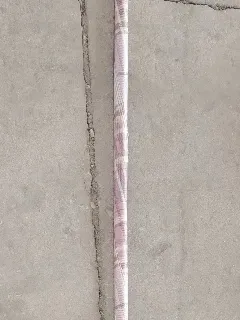

fiberglass rebar price

Understanding Fiberglass Rebar Prices An Insightful Overview

In the construction industry, the materials used can significantly influence the integrity, durability, and sustainability of a project. One such innovation that has gained traction in recent years is fiberglass rebar. Unlike traditional steel rebar, fiberglass rebar offers numerous advantages, including resistance to corrosion, lighter weight, and improved tensile strength. However, to make informed decisions regarding its use, understanding fiberglass rebar prices is crucial for contractors, builders, and architects.

Factors Influencing Fiberglass Rebar Prices

1. Raw Materials The cost of fiberglass, primarily made from fine glass fibers and resin, is a fundamental factor affecting the price of fiberglass rebar. Fluctuations in the prices of raw materials due to market demand, supply chain disruptions, or geopolitical factors can ultimately influence the overall cost of fiberglass rebar.

2. Manufacturing Process The production of fiberglass rebar is a specialized process that involves advanced technology and skilled labor. The complexity of the manufacturing process, along with the machinery used, can affect operational costs. Manufacturers that invest in high-quality production techniques may charge more for their products, but this often translates to better performance and longevity.

3. Types and Specifications Fiberglass rebar comes in various types, each with different specifications suitable for diverse applications. For instance, there are different diameters, lengths, and grades, which can significantly impact the price. Custom orders or specialized types, such as those designed for specific environmental conditions, may also result in higher costs.

fiberglass rebar price

4. Market Demand The popularity of fiberglass rebar is on the rise due to its myriad benefits, leading to increased demand in construction projects, particularly in coastal areas where corrosion from saltwater is a significant concern. Consequently, as demand surges, prices may rise. Conversely, if the market encounters an oversupply, prices may stabilize or drop.

5. Competition The growing number of manufacturers and suppliers in the fiberglass rebar industry can affect pricing dynamics. Increased competition typically leads to price wars, which can benefit consumers seeking cost-effective options. However, buyers should also consider the balance between cost and quality when selecting a supplier.

Average Price Ranges

While the prices of fiberglass rebar can vary widely, a general overview indicates that they might range from $0.75 to $2.50 per linear foot, depending on the factors discussed above. These figures are often lower than high-grade steel rebar when factoring in longevity and reduced maintenance costs over time due to fiberglass's corrosion resistance.

Conclusion

When considering the use of fiberglass rebar for construction projects, it is essential to assess not only its upfront costs but also the long-term benefits it provides. Although the initial investment might be higher than that of traditional materials, the durability and reduced need for maintenance make fiberglass rebar an attractive option for many contractors. Understanding the various factors influencing prices allows industry professionals to make informed choices that align with their project requirements and budgets. As the construction landscape evolves, fiberglass rebar positions itself as a viable and innovative alternative, promising resilience and sustainability in modern infrastructure.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025