loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

fiberglass rebar cost

The Cost of Fiberglass Rebar An In-Depth Analysis

Fiberglass rebar, also known as Glass Fiber Reinforced Polymer (GFRP) rebar, has emerged as a popular alternative to traditional steel reinforcement bars. With its unique properties, it is increasingly being used in various construction applications, particularly in environments prone to corrosion. However, a fundamental consideration for contractors and project managers is the cost associated with fiberglass rebar compared to steel rebar.

The Cost of Fiberglass Rebar An In-Depth Analysis

Despite the higher initial expenditure, fiberglass rebar offers several advantageous features that can lead to cost savings over time. One of the primary benefits of fiberglass rebar is its resistance to corrosion. Unlike steel, which can rust and degrade when exposed to moisture and chemicals, fiberglass rebar is impervious to these environmental factors. This characteristic makes it particularly suitable for projects in coastal areas, chemical plants, or locations with heavy de-icing salt use. The longevity of fiberglass rebar can reduce maintenance and replacement costs significantly, which can offset its initial higher purchase price.

fiberglass rebar cost

Additionally, fiberglass rebar is lighter than steel, which can lead to savings in transportation and handling costs. Workers can handle fiberglass rebar with greater ease, reducing labor costs on site. The ease of installation is another contributing factor, as fiberglass does not require the same level of equipment and manpower as steel rebar, leading to further savings in overall project costs.

Moreover, the thermal and electrical insulating properties of fiberglass rebar make it an excellent choice for specific applications where conductivity must be avoided. This can be particularly beneficial in projects such as bridge decks and airports, where minimizing electromagnetic interference is crucial.

It is also important to consider the potential impact of local regulations and building codes when evaluating the cost of fiberglass rebar. In some regions, the use of non-corrosive materials is recommended or even mandated, which could lead to cost benefits in terms of insurance and compliance with safety standards.

In conclusion, while the upfront cost of fiberglass rebar is higher than traditional steel, the long-term benefits in terms of durability, reduced maintenance, and ease of installation can make it a cost-effective alternative in the right circumstances. Contractors and project managers should weigh the initial investment against the potential savings over the lifespan of the project. As the construction industry increasingly focuses on sustainability and performance, fiberglass rebar presents a promising solution that warrants serious consideration. Ultimately, understanding the true cost of fiberglass rebar requires a holistic view that accounts for both immediate expenses and long-term value.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

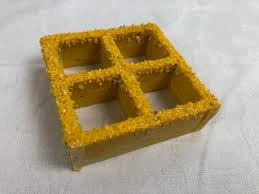

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025