loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

fiberglass grating panels

Fiberglass Grating Panels A Comprehensive Overview

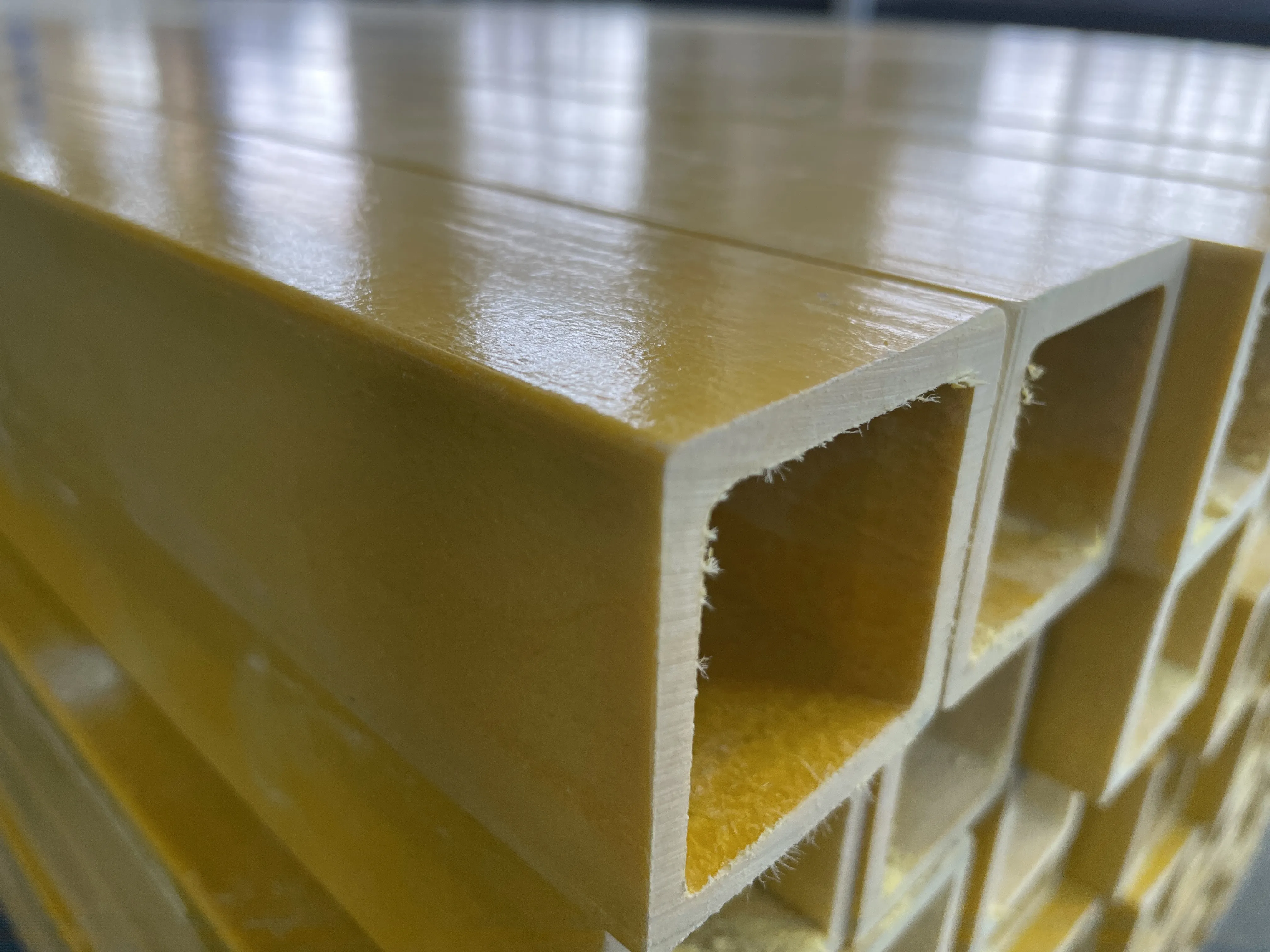

In the world of construction and industrial applications, fiberglass grating panels have emerged as a versatile and robust solution for a variety of needs. These panels are manufactured from a composite material, primarily consisting of fiberglass reinforced plastic (FRP). This unique composition imparts a host of benefits that make fiberglass grating an excellent choice for many projects. In this article, we will explore the features, advantages, and potential applications of fiberglass grating panels.

What are Fiberglass Grating Panels?

Fiberglass grating panels are engineered products that comprise a network of interwoven fiberglass strands across a resin matrix. The manufacturing process involves pultrusion or molding, resulting in a lightweight yet strong panel system. The panels can be produced in various sizes, load capacities, and designs to cater to different requirements. Their non-corrosive nature makes them ideal for environments that are prone to moisture or chemical exposure.

Key Features

1. Corrosion Resistance One of the defining characteristics of fiberglass grating panels is their exceptional resistance to corrosion. Unlike traditional steel or aluminum grating, fiberglass does not rust or corrode, which extends the lifespan of the panels and reduces maintenance costs.

2. Lightweight Fiberglass grating panels are significantly lighter than metal alternatives. This lightweight nature simplifies installation and handling, making them a practical choice for many applications.

3. Strength and Durability Despite being lightweight, fiberglass grating boasts high tensile strength due to the reinforcing fibers within the composite material. This allows for effective load-bearing capabilities, making them suitable for use in high-traffic areas.

4. Slip Resistance Many fiberglass grating products come with a textured surface or additional features to enhance slip resistance. This quality is particularly critical in environments where safety is a concern, such as industrial settings or outdoor walkways.

5. Customizable Fiberglass grating panels can be manufactured in a range of colors, sizes, and styles, allowing designers to tailor them to specific aesthetic and functional requirements. Additionally, they can be easily cut or fabricated on-site for a precise fit.

Advantages

The benefits of fiberglass grating panels extend across various sectors, including construction, manufacturing, and marine environments

.fiberglass grating panels

1. Reduced Maintenance Due to their resistance to corrosion and damage from chemicals or moisture, fiberglass panels require much less maintenance than traditional materials. This can lead to significant cost savings over time.

2. Safety Compliance Many industries have strict safety regulations. The slip-resistant qualities of fiberglass grating help in meeting these standards, reducing the likelihood of accidents on elevated surfaces.

3. Cost-Effective While the initial investment in fiberglass grating can be higher than that of metal alternatives, the long-term savings related to maintenance, replacement, and downtime make it a cost-effective choice.

4. Environmentally Friendly Fiberglass grating can be manufactured from recycled materials and is often recyclable itself. This makes it a more sustainable options in comparison to many traditional materials.

Applications

Fiberglass grating panels are utilized in a multitude of applications across various sectors

- Industrial Flooring Used in wastewater treatment facilities, chemical plants, and food processing areas, fiberglass grating offers a safe, durable walking surface that resists the harsh conditions typical of these environments.

- Walkways and Platforms In commercial and public applications, fiberglass grating provides safe pedestrian walkways, utility platforms, and viewing areas in parks or observation decks.

- Marine Applications The combination of corrosion resistance and lightweight nature makes fiberglass grating an ideal choice for boat docks, marinas, and other marine installations.

- Transportation In public transport systems, fiberglass grating is often employed in bus terminals, train stations, and airports, where durability and slip resistance are paramount.

Conclusion

Fiberglass grating panels have revolutionized the way we approach flooring and structural solutions in harsh environments. Their unique qualities—combined with safety, aesthetic flexibility, and long-term cost-effectiveness—make them an increasingly popular choice among engineers, architects, and builders. As technology progresses and industries strive for sustainable options, the role of fiberglass grating panels is likely to expand, paving the way for innovative applications that enhance safety and efficiency in construction and beyond.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025