loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

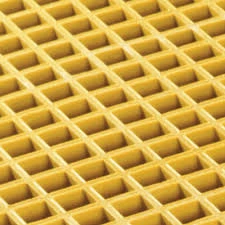

fiberglass grating panels

The Versatility and Benefits of Fiberglass Grating Panels

Fiberglass grating panels have emerged as one of the most effective solutions for a wide range of applications across various industries. Made from fiberglass reinforced plastic (FRP), these panels are renowned for their strength, durability, and resistance to environmental factors. In this article, we will explore the features, benefits, and applications of fiberglass grating panels.

What Are Fiberglass Grating Panels?

Fiberglass grating panels are composite materials consisting of woven fiberglass strands combined with resin. The result is a lightweight but robust product that can withstand heavy loads while being highly resistant to corrosion, chemical damage, and extreme weather conditions. Available in various styles, colors, and sizes, these panels can be tailored to meet specific application requirements.

Key Features

1. Corrosion Resistance Unlike traditional metal grating, fiberglass grating panels do not rust or corrode when exposed to chemicals or saltwater. This makes them ideal for industries such as wastewater treatment, chemical processing, and marine environments.

2. Lightweight Fiberglass grating is significantly lighter than steel or aluminum, which simplifies handling and installation. This characteristic also contributes to lower shipping costs and the ability to design lighter structures without compromising structural integrity.

3. High Strength-to-Weight Ratio The unique composition of fiberglass provides an impressive strength-to-weight ratio. This allows fiberglass grating panels to support heavy loads while maintaining a relatively lightweight profile.

4. Non-Conductive As electrical insulators, fiberglass grating panels are ideal for applications where electrical safety is paramount. They prevent electrical shock hazards, making them suitable for use in power plants and other industrial environments.

5. UV Resistance Fiberglass materials are inherently resistant to UV radiation, which helps maintain their structural integrity and color even after prolonged exposure to sunlight.

fiberglass grating panels

Applications

Due to their numerous advantages, fiberglass grating panels can be found in a variety of applications, including

1. Industrial Facilities These grating panels are commonly used for walkways, platforms, and stair treads in factories, refineries, and manufacturing plants due to their ability to handle heavy machinery and foot traffic.

2. Wastewater Treatment Plants Fiberglass grating is widely used in these facilities for walkways over treatment tanks and in areas where exposure to corrosive substances is common.

3. Chemical Processing The chemical resistance of fiberglass makes it an ideal choice for areas where chemicals are handled or stored, ensuring safety and longevity.

4. Marine Applications The lightweight, non-corrosive nature of fiberglass grating makes it perfect for docks, piers, and other marine structures that face harsh environmental conditions.

5. Food Processing The non-porous surface of fiberglass grating panels makes them easy to clean and hygienic, meeting stringent health and safety regulations in food processing plants.

6. Public Areas Many companies are increasingly utilizing fiberglass grating for pedestrian walkways, bridge decking, and other public spaces due to its aesthetic appeal and safety features.

Conclusion

Fiberglass grating panels represent a versatile and durable solution for various industries. Their inherent resistance to corrosion and chemicals, lightweight design, and excellent safety features make them ideal for applications ranging from industrial manufacturing to marine environments. As more industries recognize the advantages of fiberglass, it is clear that these panels are not just a fleeting trend but a robust choice for a sustainable future. As technology continues to advance, we can expect to see even more innovative uses for fiberglass grating panels, solidifying their place as a leading solution for modern engineering challenges. With their many benefits, opting for fiberglass grating is a wise decision for anyone looking to balance safety, durability, and efficiency in their projects.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025