loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

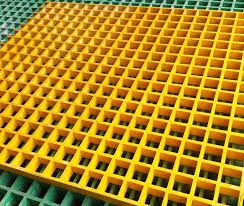

fiberglass bar grating

Understanding Fiberglass Bar Grating Its Benefits and Applications

Fiberglass bar grating is an innovative and versatile material that has gained popularity across various industries for its strength, durability, and corrosion resistance. This non-metallic product is constructed from fiberglass reinforced plastic (FRP) and is often used in applications where traditional materials like steel or aluminum would typically suffer from corrosion or require excessive maintenance. In this article, we'll explore what fiberglass bar grating is, its manufacturing process, benefits, and common applications.

What is Fiberglass Bar Grating?

Fiberglass bar grating comprises a series of parallel fiberglass bars, which are interconnected with perpendicular crossbars. The resulting structure forms a series of openings that provide a strong, lightweight grid that can support heavy loads while allowing for drainage, ventilation, and light passage. The manufacturing process involves the use of a resin that is cured with fiberglass to create a robust material that can withstand harsh environments.

Manufacturing Process

The production of fiberglass bar grating typically follows the following steps

1. Resin Application A resin, often a combination of polyester or vinyl ester, is applied to layers of fiberglass.

2. Molding and Curing The layered material is placed into a mold and cured under controlled heat and pressure to ensure optimal strength and durability.

3. Cutting and Finishing After curing, the grating is cut into specified sizes, and edges may be ground for a smoother finish. Additional treatments, such as anti-slip surfaces, can also be applied.

Benefits of Fiberglass Bar Grating

Fiberglass bar grating presents numerous advantages, making it an ideal choice for many applications

1. Corrosion Resistance One of the standout features of fiberglass grating is its resistance to corrosive substances, including chemicals, saltwater, and other harsh environments. This property makes it perfect for applications in wastewater treatment facilities, chemical processing plants, and marine environments.

fiberglass bar grating

2. Lightweight yet Strong Although it is lightweight compared to steel options, fiberglass bar grating is incredibly strong and can support substantial loads. This characteristic facilitates ease of handling and installation, reducing labor costs and time.

4. Low Maintenance The durability and corrosion resistance of fiberglass grating mean it requires minimal maintenance over its lifespan, offering long-term cost savings.

5. Customizable Fiberglass bar grating is available in various sizes, colors, and configurations, allowing for customization to meet specific project requirements.

Applications of Fiberglass Bar Grating

The versatility of fiberglass bar grating allows it to be used in a myriad of applications, including

- Walkways and Platforms Ideal for walkways and elevated platforms in industrial settings, fiberglass bar grating provides a safe, slip-resistant surface.

- Mezzanine Flooring Its strength-to-weight ratio makes it a preferred choice for mezzanine flooring in warehouses and factories.

- Drainage Covers The open design facilitates water drainage in areas prone to flooding or excess moisture.

- Public Access Areas Fiberglass grating is often used in parks, pool areas, and leisure facilities due to its aesthetic appeal and functional properties.

Conclusion

Fiberglass bar grating stands out as a highly efficient and reliable material for various industrial, commercial, and recreational applications. Its unique combination of strength, corrosion resistance, and lightweight nature make it an invaluable component across multiple sectors. As industries continue to prioritize safety and sustainability, the use of fiberglass bar grating is expected to grow, proving its worth as a smart investment for the future.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025