loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

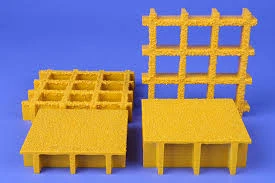

High-Quality Fiberglass Bar Grating - Durable, Lightweight, and Corrosion-Resistant Solutions

Understanding Fiberglass Bar Grating A Comprehensive Overview

Fiberglass bar grating, a versatile and durable material, has gained significant popularity across various industries for its numerous advantages. This innovative product is primarily composed of fiberglass reinforced plastic (FRP) and offers a range of benefits that make it an ideal choice for many applications.

One of the most compelling features of fiberglass bar grating is its exceptional strength-to-weight ratio. Unlike traditional steel grating, which can be heavy and cumbersome, fiberglass grating is substantially lighter, making it easier to handle and install. Despite its lightweight nature, fiberglass grating can support substantial loads, making it suitable for walkways, platforms, and other load-bearing structures.

Corrosion resistance is another significant advantage of fiberglass grating. Industries such as chemical processing, wastewater treatment, and marine applications often deal with harsh environments where materials are exposed to corrosive substances. Fiberglass grating does not rust or corrode, ensuring longevity and reducing maintenance costs. This property not only extends the lifespan of the product but also enhances safety by minimizing structural failures.

In addition to its durability, fiberglass grating offers excellent slip resistance. Many manufacturers incorporate textured surfaces or anti-slip coatings, making it a safe option for areas prone to spills or wet conditions. This feature is particularly vital in industrial settings where worker safety is paramount. The ability to prevent slips and falls contributes to a safer working environment and can help reduce the risk of accidents.

fiberglass bar grating

Another important consideration is the ease of customization. Fiberglass bar grating can be tailored to meet the specific demands of a project. It comes in various sizes, colors, and configurations, allowing for flexibility in design. Additionally, it can be fabricated to accommodate different load requirements, making it suitable for a broad range of applications, from industrial plants to commercial buildings.

Sustainability is becoming increasingly important in today’s construction and manufacturing practices. Fiberglass grating is often made from recyclable materials and is itself recyclable, aligning with eco-friendly initiatives. The production process typically involves lower energy consumption compared to traditional steel processes, further reducing its environmental impact.

Installation of fiberglass bar grating is straightforward, requiring fewer tools and less manpower than metal alternatives. It can be easily cut to size on-site, which simplifies the installation process and minimizes waste. This efficiency not only saves time but also reduces labor costs.

In conclusion, fiberglass bar grating stands out as a superior choice for various applications due to its unique combination of lightweight properties, corrosion resistance, slip prevention, and customization options. As industries continue to seek high-performance materials that enhance safety and sustainability, fiberglass bar grating is poised to play a significant role in the future of construction and infrastructure development. Its versatility and durability make it a reliable solution for modern industrial needs, ensuring that it will remain a favored material in the years to come.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025