loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Exploring the Functionality and Importance of Media Filter Vessels in Water Treatment Systems

Understanding Media Filter Vessels Key Components and Applications

Media filter vessels are crucial components in various water treatment processes across industries, ensuring the removal of impurities and enhancing the quality of water used in both industrial and municipal applications. This article delves into the fundamentals of media filter vessels, exploring their design, operational mechanisms, and significance in water treatment systems.

What is a Media Filter Vessel?

A media filter vessel is a contained unit designed to hold filtering media that play a vital role in removing particulates from liquids. These vessels can be constructed from various materials, including stainless steel, fiberglass, or carbon steel, and come in diverse sizes and configurations, depending on the specific requirements of the application.

The filtering media within these vessels can include sand, gravel, activated carbon, or specialized synthetic media. Each type of media serves a unique purpose, tailored to capture different contaminants. For instance, activated carbon is particularly effective in adsorbing organic compounds and chlorine, while sand and gravel are primarily used for particle filtration.

Working Mechanism of Media Filter Vessels

The operation of a media filter vessel is relatively straightforward yet effective. Water enters the vessel through an inlet, traveling through layers of media. As the water percolates down, particulates, sediment, and other impurities are trapped in the media layers, resulting in purified water exiting from the bottom.

media filter vessel

An essential aspect of media filter vessels is the backwashing process, which is crucial for maintaining filter efficiency. Over time, the media becomes saturated with contaminants, leading to reduced flow rates and filtration effectiveness. To address this, operators initiate a backwashing procedure that reverses the flow of water through the vessel. This process dislodges trapped particles and cleans the media, allowing it to regain its filtering capacity. Regular backwashing is essential for optimizing the performance and longevity of the media filter system.

Applications of Media Filter Vessels

Media filter vessels are utilized in a wide range of applications. In municipal water treatment plants, they are vital for producing potable water. Industries such as food and beverage, pharmaceuticals, and petrochemicals rely on media filtration to ensure the purity of water used in their processes.

In addition to drinking water treatment, media filter vessels are also employed in wastewater treatment facilities. Here, they play a key role in removing solid particles and organic materials before the water is further treated or discharged. By effectively filtering contaminants, media filter vessels contribute significantly to environmental preservation and public health.

Moreover, in industrial applications, these vessels are crucial in cooling water systems and boiler feedwater treatment. They help prevent the buildup of scales and fouling, which can lead to operational inefficiencies, equipment damage, and increased maintenance costs.

Conclusion

Media filter vessels are indispensable tools in the realm of water treatment. Their ability to remove a wide range of impurities makes them suitable for various applications, from municipal water supply to industrial processes. Understanding their design, functionality, and importance is essential for stakeholders involved in water treatment and environmental management. As water scarcity and pollution continue to pose significant challenges globally, the role of media filter vessels in ensuring clean water access cannot be overstated. Their ongoing development and optimization will be critical as industries and communities strive for sustainable water management practices.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

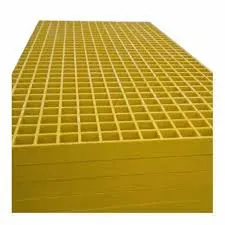

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025