loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Exploring the Expenses Involved in Fiber Reinforced Polymer Grating Solutions for Various Applications

Understanding the Cost of FRP Grating Factors, Benefits, and Applications

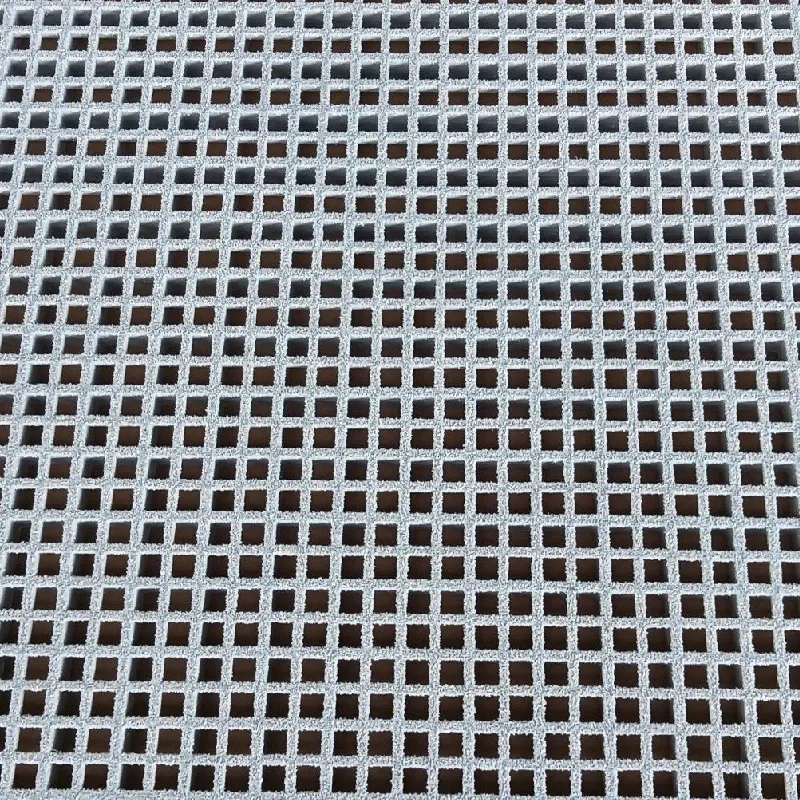

In the industrial and construction sectors, composite materials are increasingly being adopted for their durability, lightweight properties, and resistance to environmental factors. One such material gaining traction is Fiber Reinforced Plastic (FRP) grating. FRP grating serves various functions, from flooring and walkways to drainage covers and chemical containment. However, like any material, understanding the cost associated with FRP grating is crucial for businesses and contractors. This article will delve into the factors influencing the cost of FRP grating, its benefits, and its typical applications.

Factors Influencing the Cost of FRP Grating

1. Material Composition The type of fiber reinforcement and resin used can significantly affect the cost of FRP grating. Common reinforcements include glass fibers, carbon fibers, and aramid fibers, each with its own cost implications. Additionally, the choice of resin (e.g., polyester, vinyl ester, or epoxy) too plays a pivotal role in determining the overall price.

2. Manufacturing Process The production method employed for FRP grating—such as pultrusion, hand lay-up, or filament winding—can also influence costs. Pultrusion, while generally more economical for large-scale production, requires substantial initial investments in equipment. In contrast, hand lay-up may be more cost-effective for smaller quantities but is labor-intensive, leading to higher per-unit costs.

3. Dimensions and Customization Custom sizes and designs can lead to increased costs. Standard dimensions are typically more affordable due to economies of scale, while custom shapes, colors, or additional treatments (like anti-slip surfaces) can add significantly to the price.

4. Quantity Ordered Bulk purchasing can lead to substantial discounts. Economies of scale often mean that larger orders will reduce the overall cost per unit, making it financially viable for larger projects to invest in FRP grating systems.

5. Supplier and Location The choice of supplier can also impact pricing. Local manufacturers may offer competitive pricing due to lower shipping costs. However, specialized manufacturers with proprietary technologies or superior products may charge a premium.

Benefits of FRP Grating

frp grating cost

Despite the associated costs, FRP grating offers numerous advantages that make it an attractive choice

- Corrosion Resistance Unlike traditional materials, FRP is highly resistant to corrosion, making it ideal for environments exposed to chemicals, moisture, and extreme weather conditions.

- Lightweight Yet Strong FRP grating is significantly lighter than metal grating, reducing transportation and installation costs. Despite this, it retains a high strength-to-weight ratio, making it suitable for various structural applications.

- Low Maintenance The durable nature of FRP grating diminishes the need for frequent repairs or replacements, translating to long-term savings.

- Safety Features Many FRP gratings come with anti-slip surfaces, providing enhanced safety in industrial settings, which is crucial for preventing workplace accidents.

Applications of FRP Grating

FRP grating finds applications across several sectors. In industrial settings, it is extensively used for walkways, platforms, and safety barriers. It is particularly popular in the chemical processing, oil and gas, and wastewater treatment industries due to its resistance to corrosive substances. Additionally, FRP grating is an excellent choice for commercial and recreational spaces, providing safe and aesthetically pleasing flooring solutions.

Conclusion

Investing in FRP grating can present a higher initial cost when compared to traditional materials, but its long-term benefits in terms of durability, safety, and reduced maintenance can justify the expense. As industries continue to seek sustainable and efficient solutions, FRP grating stands out as a modern alternative that meets both economic and functional requirements. Understanding the factors influencing its cost is essential for making informed decisions in construction and industrial applications.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025