loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

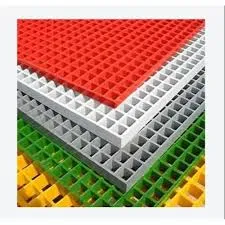

Exploring the Benefits of GRP Mesh Flooring for Various Applications

Exploring GRP Mesh Flooring Benefits and Applications

GRP mesh flooring, or Glass Reinforced Plastic mesh flooring, has been gaining popularity due to its remarkable durability, lightweight characteristics, and versatility in various applications. This innovative material combines fiberglass and resin, resulting in a flooring solution that is not only strong but also resistant to corrosion, chemicals, and adverse weather conditions. As industries seek sustainable and efficient solutions, GRP mesh flooring stands out as an ideal choice.

What is GRP Mesh Flooring?

GRP mesh flooring is constructed using woven fiberglass strands that are coated with a polymer resin. The mesh design provides excellent strength-to-weight ratio, making it an outstanding alternative to traditional flooring materials such as wood, metal, or concrete. The interlocking fibers create a sturdy surface that is both slip-resistant and effective at distributing weight, making it suitable for high-traffic areas.

Advantages of GRP Mesh Flooring

1. Durability One of the leading benefits of GRP mesh flooring is its durability. Unlike metal or wooden flooring, GRP does not corrode, rot, or degrade over time when exposed to moisture or chemicals. This makes it ideal for environments such as chemical plants, food processing areas, and outdoor facilities.

2. Lightweight The lightweight nature of GRP flooring makes it easy to handle and install. This characteristic not only reduces transportation costs but also allows for quicker installation and less structural support compared to heavier materials.

3. Slip Resistance Safety is a paramount concern in any workspace. GRP mesh flooring often comes with a textured surface that offers enhanced slip resistance. This feature is particularly beneficial in workplaces prone to spills or in wet environments, providing peace of mind to both workers and management.

4. Low Maintenance GRP flooring requires minimal maintenance. It is easy to clean, and its resistance to chemicals means that it will not stain easily. This low maintenance requirement leads to cost savings over time for businesses.

5. Sustainability As industries become more environmentally conscious, the use of GRP mesh flooring aligns with sustainable practices. The materials used can often be recycled at the end of their life cycle, reducing waste in landfills.

grp mesh flooring

Applications of GRP Mesh Flooring

The versatility of GRP mesh flooring allows it to be used in a variety of settings

- Industrial Facilities Many manufacturing and processing plants utilize GRP flooring due to its resistance to harsh chemicals and its ability to withstand heavy loads.

- Commercial Kitchens The slip-resistant surface and ease of cleaning make it an excellent choice for busy kitchens, where safety and hygiene are critical.

- Marine Environments GRP’s resistance to saltwater and corrosion makes it ideal for use on boats, docks, and other marine applications.

- Walkways and Platforms Its lightweight nature and strength allow for the creation of walkways and platforms without the need for excessive structural support.

- Agricultural Settings GRP mesh flooring is also being adopted in agricultural environments, such as livestock pens and poultry houses, due to its hygienic properties and ease of cleaning.

Conclusion

In conclusion, GRP mesh flooring offers a unique combination of strength, safety, and sustainability that caters to the demands of modern industries. As businesses strive to create efficient and safe working environments, finding the right flooring solution is crucial. With its growing range of applications and distinct advantages, GRP mesh flooring is set to become a leading choice across a multitude of sectors, ensuring that safety and durability go hand in hand. Whether for industrial use, commercial kitchens, or even outdoor environments, GRP mesh flooring is an investment that promises longevity and efficiency.

-

Premium FRP Handrail for All ApplicationsNewsAug.29,2025

-

Low Maintenance FRP Mini Mesh Grating ProductsNewsAug.29,2025

-

Innovative FRP Square Tubes for Modern Industrial SolutionsNewsAug.29,2025

-

FRP Water Storage Tanks Wholesale Solutions for Bulk BuyersNewsAug.29,2025

-

FRP Molded Grating Solutions for Diverse Industrial ApplicationsNewsAug.29,2025

-

Construction Advancements Through FRP Pultruded ProfilesNewsAug.29,2025

-

Why Choose FRP Railings, Guardrails, and Handrail Systems?NewsAug.29,2025