loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Exploring the Benefits and Applications of FRP Vessels in Modern Industries and Environmental Solutions

The Role of FRP Vessels in Modern Engineering

Fiberglass Reinforced Plastic (FRP) vessels have emerged as a pivotal component in various industries, owing to their unique properties and versatility. These vessels, made from a polymer matrix reinforced with glass fibers, offer a plethora of advantages over traditional materials such as steel and concrete. Their lightweight nature, corrosion resistance, and durability make them an ideal choice for numerous applications, particularly in chemical processing, water treatment, and transportation.

The Role of FRP Vessels in Modern Engineering

Corrosion resistance is another standout feature of FRP vessels. Many industries deal with harsh chemicals and corrosive environments that can rapidly degrade traditional materials. FRP vessels can be engineered to withstand a wide range of chemicals, including acids, alkalis, and solvents, making them suitable for use in chemical processing plants, wastewater treatment facilities, and other demanding environments. This resistance not only extends the lifespan of the vessels but also reduces maintenance costs and downtime, leading to enhanced operational efficiency.

frp vessels

Thermal insulation is another area where FRP vessels excel. The materials used in FRP construction are typically poor conductors of heat, providing excellent insulation properties. This characteristic is particularly beneficial in applications where temperature control is crucial, such as in the storage of heated or cooled liquids. By minimizing heat transfer, FRP vessels aid in maintaining optimal temperatures, ensuring the integrity of the substances contained within.

The designs and customizability of FRP vessels are yet another advantage. With advancements in manufacturing techniques, FRP can be molded into complex shapes and sizes to meet specific requirements. Whether it's a large storage tank or a smaller vessel for specialized processes, FRP can be tailored to fit the needs of any application. This flexibility also extends to aesthetics; FRP vessels can be produced in various colors and finishes, making them not only functional but also visually appealing.

Moreover, the environmental advantages of FRP vessels cannot be overlooked. As industries increasingly focus on sustainability and reducing their carbon footprint, FRP materials offer a more environmentally friendly alternative compared to traditional materials. The lighter weight aids in reducing transportation emissions, and their durability means less frequent replacements, leading to less waste. Additionally, many manufacturers now offer environmentally responsible production processes and can recycle old FRP materials, further emphasizing their commitment to sustainability.

In conclusion, FRP vessels are becoming an integral part of modern engineering solutions across various industries. Their unique properties, such as high strength-to-weight ratio, corrosion resistance, thermal insulation, and customizability, make them a superior choice over traditional materials. As industries continue to seek out efficient, durable, and environmentally responsible materials, FRP vessels are poised to play an increasingly significant role in meeting these demands. With ongoing advancements in manufacturing technology and materials science, the potential applications for FRP vessels are limitless, promising a future where they may become the standard in countless fields.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

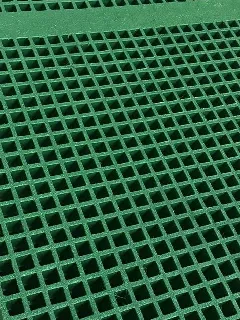

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025