loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Exploring the Benefits and Applications of FRP Square Tubes in Modern Construction

The Versatility and Applications of FRP Square Tubes

Introduction

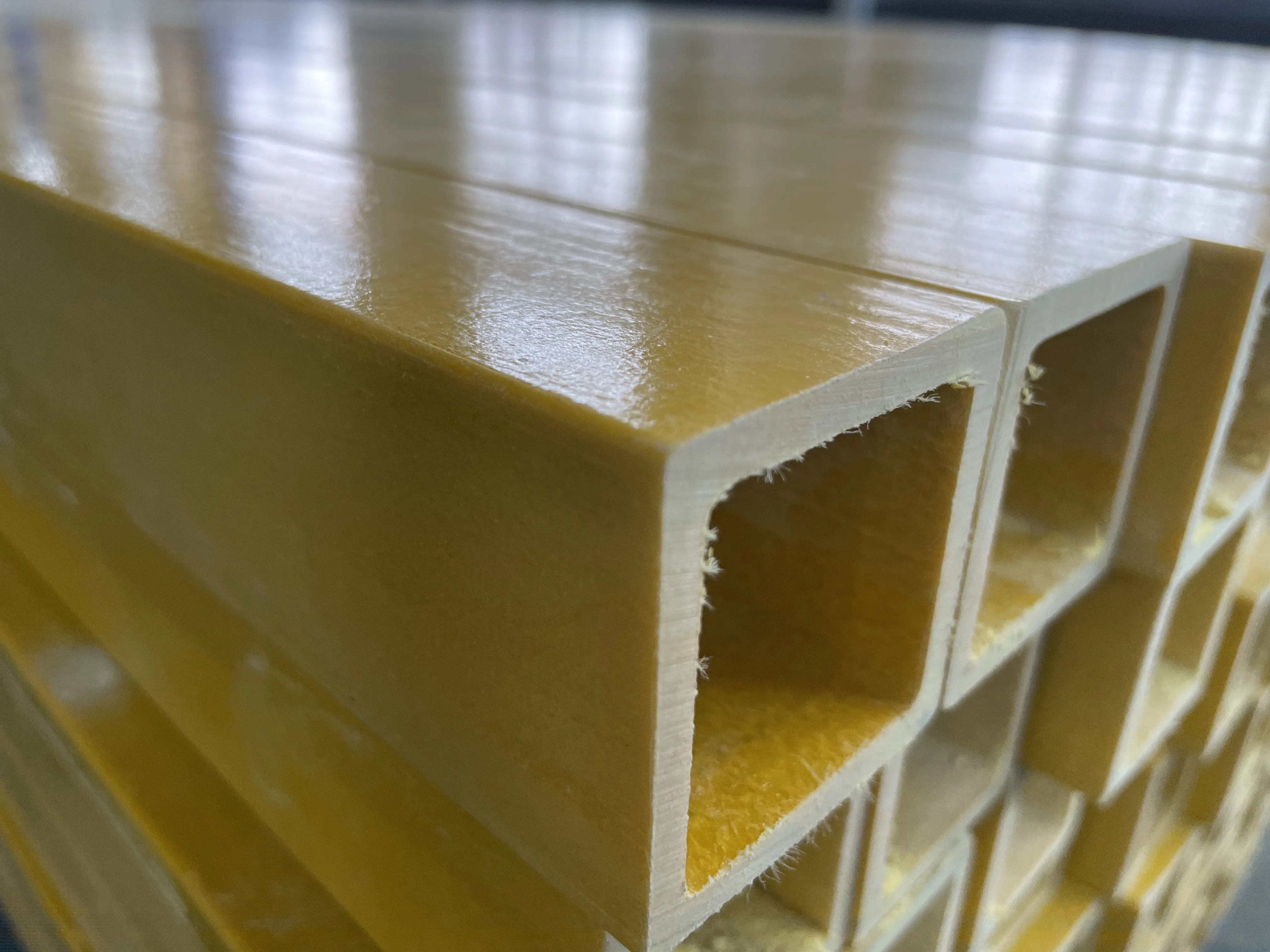

Fiber Reinforced Polymer (FRP) square tubes have emerged as an essential material in various industries due to their exceptional properties, including strength, lightweight composition, corrosion resistance, and ease of fabrication. These characteristics make FRP square tubes an attractive alternative to traditional materials like steel or aluminum. This article delves into the design, manufacturing processes, advantages, and applications of FRP square tubes.

Understanding FRP Materials

FRP is a composite material made from a polymer matrix reinforced with fibers, such as glass, carbon, or aramid. This combination results in materials that exhibit superior mechanical properties, durability, and versatility. One of the most common shapes used in construction and industrial applications is the square tube. The square tube design provides uniform strength across all sides, making it ideal for various structural and aesthetic applications.

Manufacturing Processes

The production of FRP square tubes typically involves pultrusion, a continuous process where fibers are pulled through a resin bath and then through a heated die to form the final shape. This method ensures that the fibers are evenly distributed and aligned, maximizing the strength of the finished product. Other manufacturing techniques such as filament winding and resin transfer molding can also be used depending on specific application requirements. The choice of process affects the mechanical properties and surface finish of the final product, making it essential to select the appropriate method for each application.

Advantages of FRP Square Tubes

frp square tube

One of the most significant advantages of FRP square tubes is their lightweight nature. Weighing significantly less than steel or aluminum, FRP materials contribute to reduced transportation and installation costs. Additionally, the inherent corrosion resistance of FRP makes these tubes suitable for harsh environments, such as coastal regions or chemical processing facilities, where traditional metals would quickly deteriorate.

Moreover, FRP square tubes can be easily customized in terms of dimensions, colors, and finishes, allowing for enhanced design flexibility. This customization capability, combined with their mechanical strength, allows architects and engineers to create innovative structures that were previously unfeasible with conventional materials.

Applications of FRP Square Tubes

The applications of FRP square tubes are vast and diverse. In the construction industry, they are used in a variety of structural applications, including columns, beams, and railings. Their lightweight nature allows for easier handling and quicker construction times, making them an attractive option for builders.

In the transportation sector, FRP square tubes are employed in the manufacture of lightweight components for vehicles, boats, and even aircraft. Their strength-to-weight ratio contributes to improved fuel efficiency and overall performance.

Furthermore, FRP square tubes are increasingly being utilized in the energy sector, particularly in the construction of wind turbine towers and renewable energy infrastructure. The material's resistance to environmental degradation ensures longevity and reduced maintenance costs.

Conclusion

In summary, FRP square tubes represent a significant advancement in materials science, combining strength, lightweight properties, and resistance to corrosion. Their versatility and adaptability have led to increased use across various sectors, including construction, transportation, and energy. As technology continues to evolve, the potential applications for FRP square tubes are likely to expand further, solidifying their position as a preferred material in modern engineering and design. The future of FRP materials, particularly square tubes, seems promising as industries recognize the benefits they offer over traditional materials.

-

the-expansive-industrial-reign-of-frp-pressure-vesselsNewsAug.22,2025

-

manufacturing-premium-frp-square-pipes-for-global-wholesale-excellenceNewsAug.22,2025

-

strategic-applications-for-frp-grating-solutionsNewsAug.22,2025

-

material-science-forging-grp-water-tank-longevityNewsAug.22,2025

-

the-engineered-excellence-material-science-behind-frp-railing-systemsNewsAug.22,2025

-

how-digital-pultrusion-revolutionizes-frp-profile-wholesalingNewsAug.22,2025

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025