loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Exploring the Benefits and Applications of FRP Profiles in Modern Construction

Understanding FRP Profiles A Comprehensive Overview

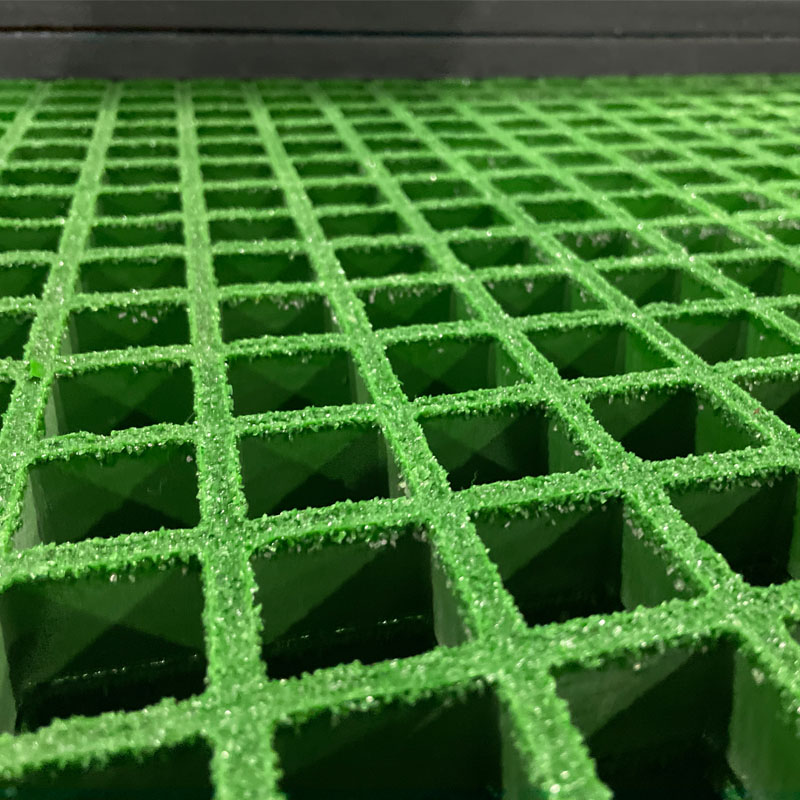

Fiberglass Reinforced Plastic (FRP) profiles have emerged as a significant innovation in modern engineering and construction, combining the strength of plastic with the durability of fiberglass. This unique composite material consists of a polymer matrix reinforced by fibers, typically glass, providing a versatile solution for various applications across numerous industries. The growing demand for lightweight, strong, and corrosion-resistant materials has propelled FRP profiles into the spotlight, making them an attractive alternative to traditional materials like steel and aluminum.

One of the most appealing features of FRP profiles is their lightweight nature. Traditional materials are often heavy, making them cumbersome and expensive to transport and install. In contrast, FRP profiles are significantly lighter, which not only reduces transportation costs but also simplifies the installation process. This lightweight feature is particularly advantageous in applications such as pedestrian bridges, where weight constraints are critical, enabling engineers to design structures that would be impractical with heavier materials.

Understanding FRP Profiles A Comprehensive Overview

Corrosion resistance is another significant advantage of FRP profiles. Traditional materials such as steel are prone to rust and degradation when exposed to harsh environmental conditions, leading to costly repairs and maintenance. In contrast, FRP profiles are inherently resistant to moisture, chemicals, and ultraviolet light, which makes them ideal for use in environments such as wastewater treatment facilities, chemical plants, and marine applications. This characteristic not only extends the lifespan of FRP structures but also reduces long-term maintenance costs, providing a more economical solution over time.

frp profiles

Thermal and electrical insulation properties of FRP profiles further enhance their appeal. Unlike metals, FRP profiles do not conduct electricity, making them safer for applications in electrical engineering and other sectors where electrical insulation is crucial. Additionally, their low thermal conductivity helps regulate temperature in applications like refrigeration or in environments where temperature fluctuations are common.

Versatility is another hallmark of FRP profiles. They can be manufactured in a variety of shapes and sizes, allowing for customized solutions to fit specific project requirements. This adaptability has made FRP profiles popular in sectors ranging from construction and automotive to aerospace and marine. The ability to mold FRP into complex geometries means designers can achieve innovative structural solutions without compromising on performance.

However, it is important to note that while FRP profiles boast numerous advantages, they are not without limitations. For instance, their production process can be more expensive than traditional materials, which may deter some industries from fully embracing them. Additionally, the recycling of FRP is still an evolving field, which presents challenges in terms of sustainability.

In conclusion, FRP profiles represent a remarkable advancement in material science, offering a combination of lightweight construction, strength, corrosion resistance, and versatility. As industries continue to seek more efficient and sustainable building solutions, the role of FRP profiles will likely expand, paving the way for innovative applications that enhance performance while reducing environmental impact. The future of engineering and construction may very well lie in the adoption and evolution of FRP technology, making it an exciting area to watch in the coming years.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025