loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Exploring the Benefits and Applications of FRP Moulded Grating in Various Industries

The Advantages and Applications of FRP Moulded Grating

Fiber Reinforced Plastic (FRP) moulded grating has emerged as a revolutionary material in various industrial and commercial sectors. Renowned for its strength, durability, and versatility, FRP grating is increasingly being adopted over traditional materials like steel and wood. This article delves into the properties, advantages, and applications of FRP moulded grating.

Understanding FRP Moulded Grating

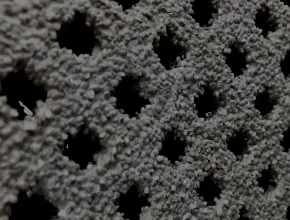

FRP moulded grating is a composite material that consists of a polymer matrix reinforced with fibers, usually glass or carbon. The manufacturing process often involves the combination of resin and fiberglass, which is then moulded into a grating form. The result is a lightweight yet remarkably strong product that is resistant to corrosion, chemicals, and UV radiation.

Key Advantages of FRP Moulded Grating

1. Corrosion Resistance One of the primary advantages of FRP grating is its ability to withstand harsh environments. Unlike metal grating, which can rust when exposed to moisture and corrosive substances, FRP remains unaffected. This makes it ideal for use in chemical processing plants, wastewater treatment facilities, and marine applications.

2. Lightweight Design FRP grating is significantly lighter than steel or aluminum alternatives. This characteristic not only makes it easier to handle and install but also reduces the load on supporting structures. This feature is particularly beneficial in applications where weight is a concern.

3. Low Maintenance The durability of FRP means that it requires less maintenance over its lifespan compared to traditional materials. This results in lower long-term costs for businesses that utilize it.

4. Slip Resistance FRP grating can be manufactured with a textured surface, providing superior slip resistance. This feature ensures safety in environments where spills or wet conditions are common, making it suitable for pedestrian walkways, platforms, and stairways.

5. Customizable FRP moulded grating can be produced in various colors, sizes, and configurations to meet specific design requirements. This level of customization enables architects and engineers to create tailored solutions for their projects.

frp moulded grating

Applications of FRP Moulded Grating

The versatility of FRP moulded grating has led to its application across a wide range of industries

- Chemical Processing In environments where chemical spills are a risk, FRP grating offers the necessary resistance to prevent damage and ensure safety.

- Water and Wastewater Treatment Due to its corrosion resistance, FRP is commonly used in water treatment plants to create walkways, platforms, and covers.

- Maritime Industry The marine environment can be incredibly harsh on materials, but FRP's resistance to saltwater and UV rays makes it an ideal choice for docks, piers, and offshore applications.

- Food Processing The non-porous nature of FRP grating makes it easy to clean, which is crucial in the food processing industry where hygiene is paramount.

- Industrial Facilities In factories and manufacturing plants, FRP grating is used to create durable walkways and platforms that withstand heavy foot and equipment traffic.

Conclusion

FRP moulded grating represents an innovative solution that meets the demands of modern industrial and commercial applications. With its impressive strength-to-weight ratio, corrosion resistance, and low maintenance needs, it offers a reliable alternative to traditional materials. As industries continue to evolve, the adoption of FRP grating is likely to increase, solidifying its place as a preferred choice for construction and engineering projects worldwide. In the quest for sustainable and long-lasting materials, FRP moulded grating stands at the forefront, offering both performance and versatility.

-

Premium FRP Handrail for All ApplicationsNewsAug.29,2025

-

Low Maintenance FRP Mini Mesh Grating ProductsNewsAug.29,2025

-

Innovative FRP Square Tubes for Modern Industrial SolutionsNewsAug.29,2025

-

FRP Water Storage Tanks Wholesale Solutions for Bulk BuyersNewsAug.29,2025

-

FRP Molded Grating Solutions for Diverse Industrial ApplicationsNewsAug.29,2025

-

Construction Advancements Through FRP Pultruded ProfilesNewsAug.29,2025

-

Why Choose FRP Railings, Guardrails, and Handrail Systems?NewsAug.29,2025