loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Exploring the Advantages of FRP Pultruded Sections in Modern Construction Applications

Understanding FRP Pultruded Sections Properties, Applications, and Benefits

Fiber-Reinforced Polymer (FRP) pultruded sections are an innovative solution in the realm of construction and engineering materials, offering unparalleled advantages over traditional materials such as steel and concrete. The pultrusion process, which combines continuous fiber reinforcement and thermosetting resin, results in lightweight, high-strength components that cater to a wide range of applications.

What Are FRP Pultruded Sections?

Pultruded sections are created through a manufacturing process known as pultrusion. In this process, continuous fibers—such as glass, carbon, or aramid—are pulled through a resin bath and then through a heated die, where they cure into a solid shape. This manufacturing method ensures that the fibers are oriented in the direction of the load, resulting in materials with superior mechanical properties. The resultant FRP sections are homogenous, avoiding the voids and weaknesses often found in traditional materials.

Key Properties of FRP Pultruded Sections

1. High Strength-to-Weight Ratio One of the primary advantages of FRP pultruded sections is their high strength-to-weight ratio. This feature makes them an ideal choice for applications where lightweight materials are crucial without compromising strength.

2. Corrosion Resistance Unlike metals that can rust or corrode over time, FRP materials are highly resistant to chemical and environmental degradation. This property significantly extends the lifespan of structures, particularly in marine and chemical environments.

3. Electrical Insulation FRP sections are excellent electrical insulators, making them suitable for applications in environments where electrical conductivity poses a risk.

4. Thermal Stability FRP pultruded sections maintain their structural integrity under a wide range of temperatures, allowing for their use in both hot and cold environments.

5. Low Maintenance Due to their superior durability and resistance to corrosion and environmental factors, FRP sections require minimal maintenance, translating to cost savings over time.

frp pultruded sections

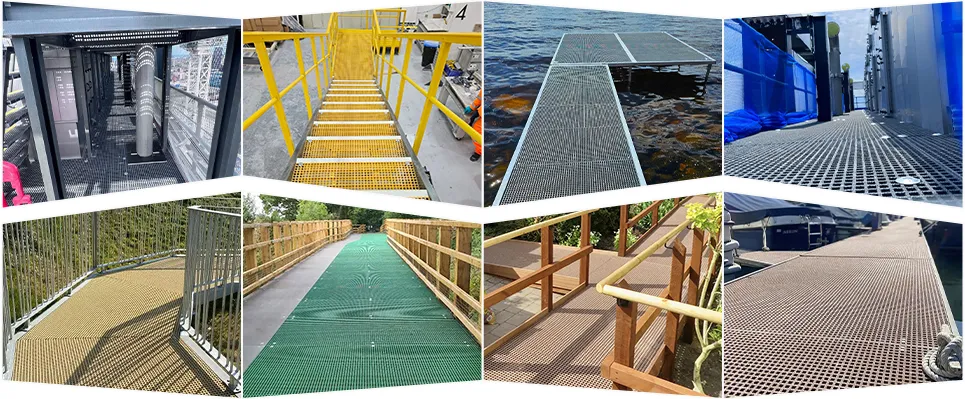

Applications of FRP Pultruded Sections

The versatility of FRP pultruded sections allows for their application across various industries, including

1. Infrastructure Used in bridge construction, railings, and supports, FRP sections provide lightweight and corrosion-resistant solutions that enhance overall safety and longevity.

2. Transportation The automotive and aerospace industries benefit from the lightweight properties of FRP, which contribute to improved fuel efficiency and performance.

3. Construction In building applications, FRP can be utilized for window frames, cladding, and reinforcement for ceilings and floors.

4. Electrical With their electrical insulation properties, FRP sections are ideal for utility poles, cable trays, and other electrical infrastructure.

5. Water Management FRP materials are increasingly used in water treatment facilities and sewage systems due to their resistance to chemical attack and hydrodynamic properties.

Conclusion The Future of FRP Pultruded Sections

As industries continue to seek sustainable, high-performance materials, the adoption of FRP pultruded sections is likely to increase. Their unique combination of lightweight, strength, and durability positions them as a superior alternative to traditional materials. With ongoing advancements in manufacturing technology and material science, the potential applications for FRP pultruded sections are vast and growing, promising to revolutionize construction and engineering for years to come.

In summary, FRP pultruded sections not only offer immediate benefits in specific applications but also represent a forward-thinking solution that aligns with modern engineering challenges and sustainability goals. Their expanding role in diverse sectors reflects a shift towards innovative materials that meet the demands of a changing world.

-

Premium FRP Handrail for All ApplicationsNewsAug.29,2025

-

Low Maintenance FRP Mini Mesh Grating ProductsNewsAug.29,2025

-

Innovative FRP Square Tubes for Modern Industrial SolutionsNewsAug.29,2025

-

FRP Water Storage Tanks Wholesale Solutions for Bulk BuyersNewsAug.29,2025

-

FRP Molded Grating Solutions for Diverse Industrial ApplicationsNewsAug.29,2025

-

Construction Advancements Through FRP Pultruded ProfilesNewsAug.29,2025

-

Why Choose FRP Railings, Guardrails, and Handrail Systems?NewsAug.29,2025