loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

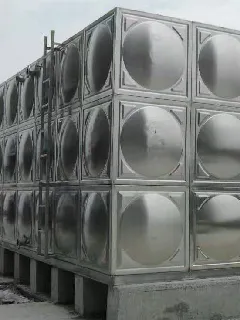

Exploring the Advantages and Features of SMC Panel Tanks for Water Storage Solutions

Understanding SMC Panel Tanks A Durable Solution for Water Storage

In today's industrial world, the demand for reliable and efficient water storage systems has never been greater. Among the various types of storage solutions available, SMC (Sheet Molding Compound) panel tanks have emerged as a popular choice for many applications. These tanks are designed to store a wide range of liquids, including drinking water, industrial water, and wastewater, offering numerous advantages over traditional materials such as steel and concrete.

What are SMC Panel Tanks?

SMC panel tanks are prefabricated storage systems made from an advanced composite material known as Sheet Molding Compound. This material is composed of a mixture of fiberglass, resin, and other additives, which are molded under heat and pressure to create strong, lightweight panels. These panels are then assembled on-site to create a customized tank that meets specific storage requirements. The modular design of SMC tanks allows for flexibility in capacity and shape, making them suitable for various applications, including municipal, agricultural, and industrial uses.

Key Advantages of SMC Panel Tanks

1. Corrosion Resistance One of the standout features of SMC panels is their excellent corrosion resistance. Unlike metal tanks that are susceptible to rust and deterioration, SMC tanks maintain their integrity over time, even when exposed to harsh environmental conditions or aggressive chemicals. This durability ensures a longer service life, reducing the need for frequent repairs or replacements.

2. Lightweight and Easy to Install The lightweight nature of SMC panels makes them easy to transport and install. Unlike heavy concrete or metal tanks, SMC tanks can be handled by fewer personnel and do not require heavy machinery for installation. This ease of handling can lead to significant savings in labor costs and installation time.

smc panel tank

3. Excellent Insulation Properties SMC materials provide good insulation, which can be particularly beneficial for storing temperature-sensitive liquids. This insulation helps maintain the temperature of the stored liquid, reducing energy costs associated with heating or cooling and ensuring the quality of the liquid over time.

4. Customizable Designs SMC panel tanks can be easily customized to fit specific dimensions and capacity requirements. Whether you need a small tank for a rural water supply or a large tank for industrial applications, the modular design allows for scalability, making SMC tanks highly versatile.

5. Cost-Effective Solution While the initial investment in SMC panel tanks may be higher than some traditional options, the long-term benefits in durability, maintenance, and operational costs make them a cost-effective solution for many businesses and municipalities. Their longevity and reduced need for repairs translate into lower total ownership costs.

Applications of SMC Panel Tanks

SMC panel tanks are suitable for a wide range of applications. They are commonly used for drinking water storage in municipalities, irrigation systems in agriculture, and industrial processes where water storage is essential. Additionally, SMC tanks are often employed in fire-fighting systems, where reliable water availability is critical. Their corrosion resistance and durability make them an ideal choice for wastewater treatment facilities, contributing to environmental sustainability.

Conclusion

In conclusion, SMC panel tanks represent a modern solution to water storage challenges. Their impressive range of benefits, including corrosion resistance, lightweight construction, excellent insulation properties, and customization options, make them a preferable choice for various sectors. As industries continue to seek sustainable and durable storage solutions, SMC panel tanks stand out as an innovative option that meets the needs of both today and tomorrow. With their growing popularity, SMC tanks are poised to play a significant role in the future of water management and storage solutions.

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025

-

The Strength and Durability of FRP GratingNewsMay.21,2025

-

The Importance of Water Treatment Systems for Clean and Safe WaterNewsMay.21,2025

-

The Advantages of FRP Rebar for Construction ProjectsNewsMay.21,2025

-

Say Goodbye to Hard Water with a Reliable Water SoftenerNewsMay.21,2025

-

Maximize Your Water Storage with a Sectional Water TankNewsMay.21,2025

-

The Power of Filter VesselsNewsMay.19,2025