loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Exploring the Advantages and Applications of FRP Sheet Piling in Modern Construction Projects

The Advantages of FRP Sheet Piling in Modern Engineering

Fiberglass Reinforced Polymer (FRP) sheet piling has emerged as a significant innovation in the field of civil engineering and construction. Characterized by its lightweight nature and impressive strength-to-weight ratio, FRP sheet piling is increasingly being utilized for various applications, particularly in marine environments, waterfront projects, and soil retention systems. This article explores the benefits of FRP sheet piling and its growing importance in modern engineering practices.

Corrosion Resistance

One of the most significant advantages of FRP sheet piling is its exceptional resistance to corrosion. Unlike traditional materials such as steel, which can deteriorate when exposed to water, salt, and other environmental factors, FRP is inherently resistant to these conditions. This property makes FRP sheet piling particularly suitable for marine and coastal projects where structures are in constant contact with water and high salinity environments. The longevity and durability of FRP sheet piling reduce maintenance costs and prolong the life of structures significantly.

Lightweight and Easy Installation

Another notable feature of FRP sheet piling is its lightweight composition. FRP products are considerably lighter than their steel or concrete counterparts, allowing for easier handling and transportation. This property not only reduces the overall construction costs but also facilitates faster installation, as heavy lifting equipment may not be necessary. The ease of installation also minimizes disruption to surrounding environments and reduces the overall carbon footprint associated with construction projects.

High Strength and Flexibility

Despite its lightweight nature, FRP sheet piling offers a high strength-to-weight ratio, making it particularly effective for retaining soil and resisting lateral loads. The flexibility of FRP allows it to be adapted to various project requirements and site conditions. Engineers can design solutions that leverage the material's properties to create robust systems that can withstand substantial pressures without compromising stability.

frp sheet piling

Design Versatility

FRP sheet piling comes in various shapes, sizes, and colors, which enhances its versatility in design. This adaptability allows architects and engineers to create aesthetically pleasing structures that harmonize with the surrounding environment. Whether used for sea walls, riverbanks, or landscape features, FRP sheet piling can be customized to meet specific project requirements while providing the necessary structural integrity.

Environmental Benefits

Utilizing FRP sheet piling also yields environmental benefits. The reduced need for maintenance and replacement translates into lower resource consumption over the long term. Moreover, FRP is often produced using sustainable practices, which aligns with the growing emphasis on environmentally-friendly construction methods. As society increasingly values sustainability, the adoption of FRP materials in construction projects contributes to reducing the ecological footprint.

Applications in Various Fields

FRP sheet piling is not limited to marine applications; its uses extend into other fields as well. For instance, it is employed in retaining walls, sewage systems, and even in industrial settings for chemical containment. Its ability to withstand harsh environments while maintaining its structural integrity makes it a preferred choice across diverse sectors.

Conclusion

In summary, FRP sheet piling presents a modern solution to age-old engineering challenges. Its corrosion resistance, lightweight nature, high strength, design versatility, environmental benefits, and broad range of applications make it an attractive option for engineers and architects worldwide. As technology continues to advance, the use of FRP in construction is expected to grow, paving the way for more sustainable, efficient, and resilient engineering practices.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

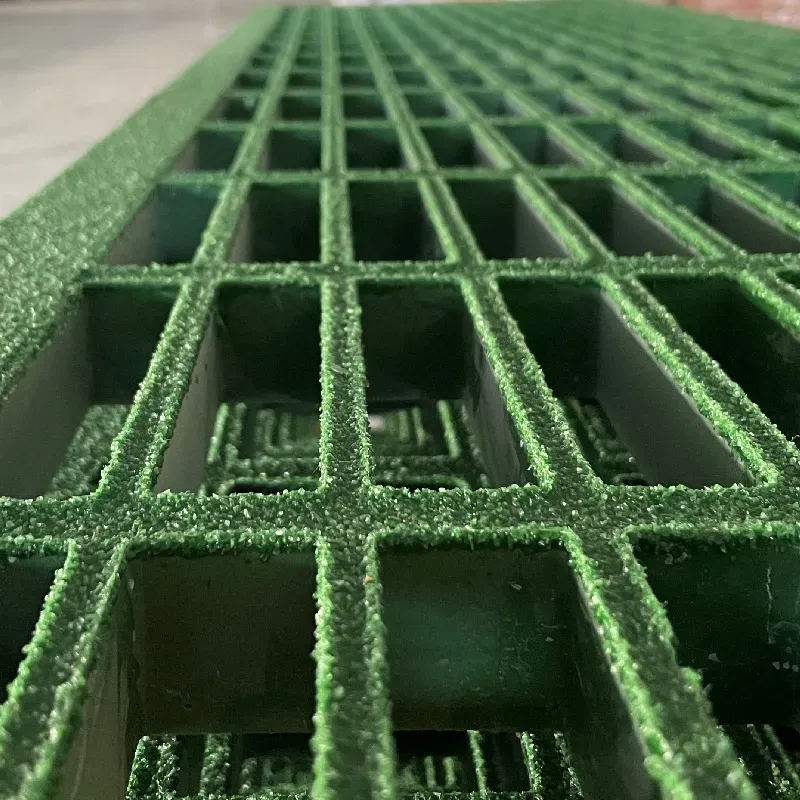

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025