loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Exploring Properties and Applications of Mild Steel in Circular Hollow Section Design and Engineering

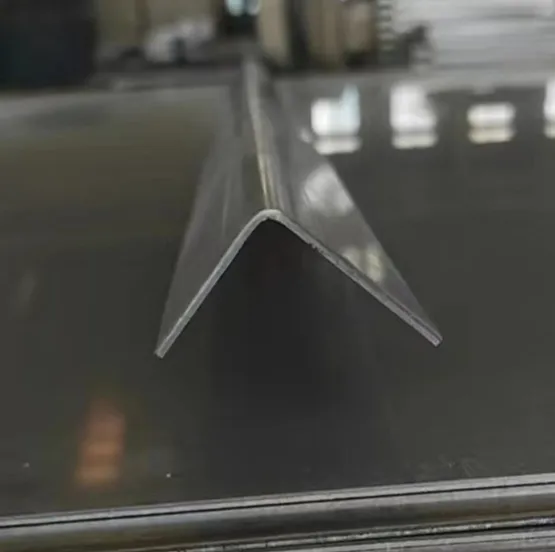

Mild Steel Circular Hollow Section An Overview

Mild steel, also known as low carbon steel, is a versatile material widely used in various engineering and construction applications. One of the most popular forms of mild steel utilized in the structural sector is the circular hollow section (CHS). Characterized by its cylindrical shape and hollow core, the circular hollow section is favored for its structural efficiency and aesthetic appeal in both construction and fabrication.

Properties of Mild Steel

Mild steel typically contains a carbon content of less than 0.25%, which imparts a range of beneficial properties. It has good weldability, ductility, and malleability, making it an ideal choice for construction applications. The material is also relatively cheap compared to other high-strength alloys, allowing for cost-effective construction solutions. Mild steel can withstand various stresses and strains, making it suitable for structures subjected to dynamic loadings, such as bridges and buildings.

Design and Structural Benefits

The circular hollow section exhibits several design advantages, notably its ability to handle axial loads and bending moments effectively. The cylindrical shape of CHS allows for uniform distribution of stress across its perimeter, which enhances its structural capacity. This efficiency means that less material is required in comparison to other shapes, such as square or rectangular hollow sections, when carrying the same load.

Moreover, the circular shape lends itself well to torsional loads, making CHS an excellent choice for applications where twisting forces are present. The aesthetic appeal of circular hollow sections is also noteworthy; their smooth, rounded appearance is often preferred in architectural designs, providing both form and function.

Applications

mild steel circular hollow section

The applications of mild steel circular hollow sections span various industries. In the construction sector, CHS is widely used in building frames, columns, and bracing systems, as its strength-to-weight ratio allows for the creation of lighter structures without compromising safety. Furthermore, CHS finds applications in the manufacturing of vehicles, where its strength and lightweight characteristics contribute to better fuel efficiency.

In the realm of infrastructure, circular hollow sections are integral in the construction of bridges, towers, and transmission poles. Their capacity to withstand environmental factors, such as wind and seismic activity, ensures that these structures remain robust and durable over time.

Fabrication Techniques

The fabrication of circular hollow sections typically involves processes such as cold forming, welding, or hot rolling. Cold-formed sections are produced by shaping the steel at room temperature, resulting in improved mechanical properties due to the strain hardening effect. Welded CHS can be constructed from flat plates, allowing for customized dimensions that suit specific project requirements.

Corrosion protection is also a key consideration in the fabrication and use of mild steel CHS. While mild steel is susceptible to rust, various protective coatings, such as galvanization or painting, can enhance its longevity and performance in outdoor environments.

Conclusion

Mild steel circular hollow sections represent an important advancement in structural engineering, blending strength, versatility, and aesthetic appeal. Their unique properties make them an increasingly popular choice in both construction and industrial applications. As the demand for efficient and sustainable building materials continues to grow, circular hollow sections will undoubtedly play a significant role in the future of structural design. With ongoing improvements in fabrication techniques and protective measures, the potential of mild steel CHS is set to expand even further, reinforcing its place in modern engineering solutions.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025