loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Designing an Effective Filtration System Using Advanced Media Filter Vessel Technology for Water Treatment

Understanding Media Filter Vessels A Comprehensive Overview

In the realm of water treatment and filtration, media filter vessels play an essential role in ensuring the purity and clarity of water. These vessels are critical components in various industrial applications, municipal water supply systems, and even swimming pools, where the quality of water is paramount. This article will delve into the design, operation, and importance of media filter vessels in water filtration processes.

What is a Media Filter Vessel?

A media filter vessel is a container designed to hold specific filtration media, which can be sand, carbon, gravel, or other materials, used to remove suspended solids, sediments, and contaminants from water. The vessel's design typically features an inlet and outlet for water flow, and it can vary in size from small residential units to large industrial setups capable of processing thousands of gallons per minute.

How Does It Work?

The operation of a media filter vessel is relatively straightforward. Water enters the vessel through an inlet and passes through the filtration media. As water flows through the layers, particles and impurities are trapped within the media. The effectiveness of filtration depends on several factors, including the type of media used, the flow rate, and the design of the vessel itself.

The filtration process can be categorized into two stages

1. Coarse Filtration In this initial stage, larger particles are removed quickly. This stage is essential for protecting the finer media below from clogging too soon.

2. Fine Filtration Here, smaller particles are captured. Depending on the media used, this stage can achieve high levels of cleanliness, removing contaminants that are often invisible to the naked eye.

Types of Media Used

media filter vessel

Various types of filtration media can be utilized in media filter vessels, each with specific characteristics and applications. Some of the most common types include

- Sand Widely used due to its availability and effectiveness in removing larger particulates. - Activated Carbon Known for its adsorptive properties, it effectively removes chemicals, odors, and tastes from water. - Gravel Often used as a support layer for finer media to prevent clogging and enhance water flow. - Membrane Filters These provide a physical barrier to contaminants and are suitable for applications requiring high purity.

Importance in Water Treatment

Media filter vessels are vital in several sectors, including

- Municipal Water Treatment Ensuring the delivery of clean water to communities, helping to protect public health. - Industrial Processes Supporting operations that require high-quality water, such as in food and beverage production. - Swimming Pools and Spas Maintaining water clarity and safety for recreational use.

By employing media filter vessels, operators can significantly reduce the presence of harmful contaminants, which helps prevent illnesses and enhances the overall safety of water supplies.

Maintenance and Challenges

While media filter vessels are effective, they do require regular maintenance to ensure optimal performance. The filtration media can become clogged over time, necessitating backwashing or replacement. Additionally, improper setup or neglecting regular checks can lead to reduced filtration efficiency or even system failure.

In conclusion, media filter vessels are indispensable in the water treatment industry, providing an efficient means of achieving clean and safe water. As technology advances, efforts continue to improve the design and efficiency of these vessels, ensuring they remain a cornerstone in the quest for high-quality water. Understanding their operation and importance is crucial for anyone involved in water treatment processes, as it directly impacts public health and environmental sustainability.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

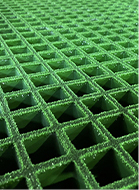

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025