loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Design and Applications of Grating Floor Plates in Modern Architecture and Industry

Grating Floor Plates An Overview of Functionality and Applications

Grating floor plates, also known as metal grating or floor grates, are essential components in various industrial and commercial applications. These structures are primarily made from metal such as steel, aluminum, or fiberglass and are characterized by their open designs, allowing for excellent drainage and airflow while providing safety and support underfoot. The use of grating floor plates extends across numerous sectors, including construction, manufacturing, and marine environments.

Key Features and Benefits

One of the most notable features of grating floor plates is their ability to enhance safety in environments where fluid spills are common. The open design allows liquids to flow through, significantly reducing the risk of slipping. This makes them particularly suitable for food processing plants, chemical facilities, and other industrial sites where spills may occur. Furthermore, their non-slip surface is engineered to provide traction, thus making these plates a safe choice for both pedestrians and industrial equipment.

Additionally, grating floor plates are lightweight yet robust, a characteristic that simplifies installation without compromising structural integrity. They come in various configurations, sizes, and materials, allowing for customized solutions depending on the specific requirements of the project. For instance, fiberglass grating offers corrosion resistance, making it ideal for environments exposed to harsh chemicals and seawater.

Versatile Applications

Grating floor plates are utilized in a wide range of applications. In industrial settings, they are commonly found in walkways, platforms, and catwalks where workers require safe passage above hazardous areas or equipment. They ensure optimal visibility for operators while allowing debris and spills to fall through, contributing to a cleaner work environment.

grating floor plate

In the construction industry, grating plates are employed in flooring systems, drainage applications, and as stair treads. Their ability to withstand heavy loads makes them suitable for factories, warehouses, and transportation facilities. Moreover, they can be used in architectural projects to create visually interesting and functional designs in urban environments, such as parks, pedestrian bridges, and public squares.

Marine applications also benefit from the use of grating floor plates. For example, they are used in shipbuilding to create walkways and loading docks, where exposure to water and moisture is a concern. Their resistance to rust and corrosion ensures longevity and reduces maintenance costs over time.

Environmental Considerations

With a growing emphasis on sustainability, the production and use of grating floor plates have evolved to include eco-friendly materials and manufacturing processes. Many manufacturers have begun to incorporate recycled metals and environmentally friendly coatings, significantly reducing the carbon footprint associated with their production. Furthermore, the durability and longevity of grating plates mean they do not need to be replaced as frequently, further contributing to sustainability efforts.

Conclusion

Grating floor plates represent a critical innovation in industrial safety and efficiency. Their unique design not only enhances traction and prevents slips and falls, but they also facilitate drainage and airflow in various industrial settings. With their diverse applications across sectors, from manufacturing to marine environments, their importance cannot be overstated. As we move towards more sustainable practices, the development of grating floor plates will continue to incorporate environmentally conscious materials and designs. Ultimately, their role in improving safety and functionality in industrial and commercial applications will ensure they remain a vital resource for years to come.

-

Premium FRP Handrail for All ApplicationsNewsAug.29,2025

-

Low Maintenance FRP Mini Mesh Grating ProductsNewsAug.29,2025

-

Innovative FRP Square Tubes for Modern Industrial SolutionsNewsAug.29,2025

-

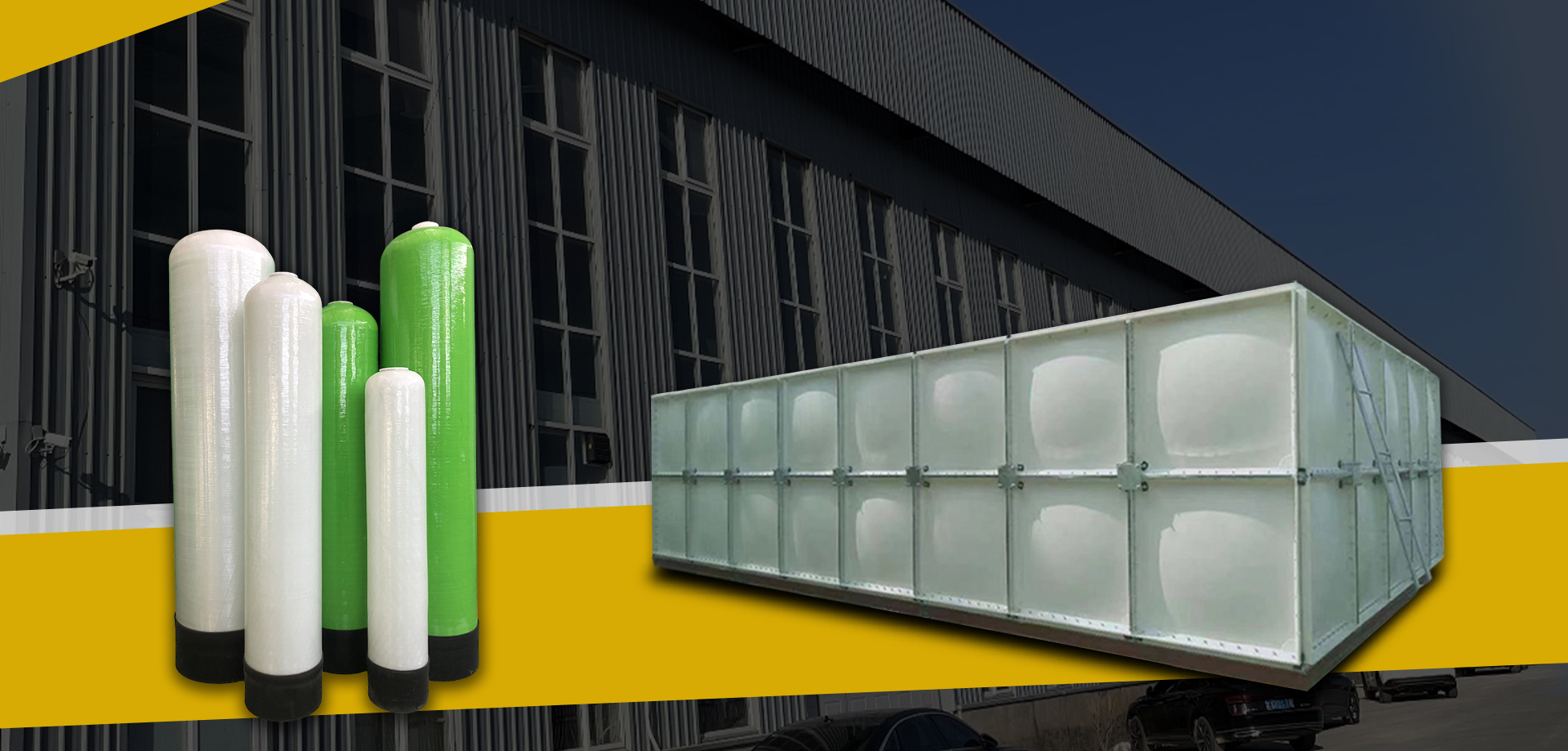

FRP Water Storage Tanks Wholesale Solutions for Bulk BuyersNewsAug.29,2025

-

FRP Molded Grating Solutions for Diverse Industrial ApplicationsNewsAug.29,2025

-

Construction Advancements Through FRP Pultruded ProfilesNewsAug.29,2025

-

Why Choose FRP Railings, Guardrails, and Handrail Systems?NewsAug.29,2025