loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

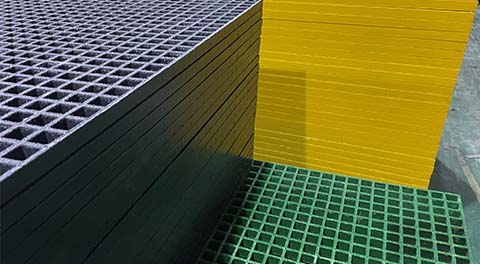

cutting frp grating

Cutting FRP Grating A Comprehensive Guide

Fiber Reinforced Plastic (FRP) grating is a versatile material commonly used in various industrial applications due to its light weight, high strength, and corrosion resistance. Its unique properties make it an ideal choice for environments where traditional materials like metal or wood may fail. However, to achieve the right fit and functionality, precise cutting of FRP grating is essential. In this article, we will delve into the methods and best practices for cutting FRP grating effectively.

Understanding FRP Grating

Before delving into the cutting process, it is crucial to understand the characteristics of FRP grating. Made from a matrix of fiberglass and resin, FRP grating is available in different styles, including molded and pultruded types. Its non-slip surface is perfect for walkways, platforms, and even marine applications. The lightweight nature of FRP grating allows for easier handling and installation, making it a popular choice for various projects.

Tools Required for Cutting FRP Grating

When it comes to cutting FRP grating, having the right tools is paramount. Typically, you will need

1. Circular Saw A standard circular saw with a carbide-tipped blade is ideal for cutting FRP grating. The blade should have fine teeth to ensure a smooth cut without chipping the material. 2. Jigsaw For more intricate cuts, a jigsaw equipped with a fine-toothed blade can be employed. This is particularly useful for creating curves or detailed shapes.

4. Cutting Guide A straight edge or cutting guide helps ensure straight and accurate cuts.

5. Personal Protective Equipment (PPE) Safety goggles, gloves, and a dust mask are essential to protect yourself from dust and debris during the cutting process.

cutting frp grating

Preparing for the Cut

Before starting the cutting process, gather all necessary materials and ensure you have a clean, well-ventilated workspace. Measure the grating accurately, marking out the cut lines clearly with a marker or chalk. Double-check your measurements to avoid any costly mistakes.

Cutting FRP Grating

1. Secure the Grating Use clamps to secure the grating firmly to your work surface. This will prevent any movement during cutting and ensure a straight, clean line.

2. Set Your Tool Depending on the tool you are using, adjust it according to the thickness of the grating. Make sure that the blade is properly installed and in good condition.

3. Cut at a Steady Pace Start cutting slowly and steadily, allowing the saw to do the work. Rushing the process may lead to uneven cuts or damage to the material.

4. Cooling Down FRP can generate heat when cut; therefore, periodically check the blade’s temperature and allow it to cool down if necessary to avoid melting the resin.

5. Finishing Touches After cutting, use sandpaper or a grinding tool to smooth out the edges of the cut. This will not only ensure safety but also enhance the appearance of the finished product.

Conclusion

Cutting FRP grating can be a simple and effective process when approached with the right tools and techniques. By following the outlined steps and taking the necessary safety precautions, you can ensure that your FRP grating fits perfectly and performs optimally in its intended application. As industries continue to recognize the benefits of FRP, mastering the art of cutting this unique material will become an increasingly valuable skill in the field. Whether for industrial use, construction, or decorative purposes, properly cut FRP grating can provide lasting durability and performance in even the harshest environments.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025