loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

circular hollow section steel

Understanding Circular Hollow Section Steel Properties and Applications

Circular Hollow Section (CHS) steel is a versatile and widely used material in modern engineering and construction. Characterized by its circular shape and hollow center, CHS steel offers a multitude of advantages over traditional solid steel sections, making it a popular choice for various applications in structural engineering, architecture, and manufacturing.

Structural Benefits

One of the primary advantages of CHS steel is its excellent structural efficiency. The circular cross-section allows for uniform distribution of stress around the entire perimeter, which results in high resistance to bending, torsion, and axial loads. This property makes CHS ideal for applications such as columns, beams, and trusses, where strength and stability are paramount. The hollow nature of the section also contributes to reduced weight, allowing for lighter structures without compromising integrity.

Aesthetic Appeal

Beyond its structural benefits, CHS steel is often favored for its aesthetic appeal. The smooth, rounded surfaces provide a modern and sleek look, which can enhance the architectural vision of a project. Many architects choose CHS for exposed structures, as it contributes to an open and airy feel, integrating seamlessly into contemporary designs. Additionally, CHS can be easily welded and connected to other structural elements, enabling creative design solutions.

Lightweight Construction

The reduced weight of CHS steel compared to traditional solid sections translates to cost savings in several areas. Lighter sections require less material, which can lower production costs and reduce the environmental impact associated with steel manufacturing. Furthermore, the decreased weight leads to easier handling and transportation, which can significantly lower construction costs by minimizing labor and logistics requirements on-site.

Versatility in Applications

circular hollow section steel

CHS steel is utilized in a wide array of applications across different industries. In the construction sector, it is commonly employed for both structural and non-structural purposes, including buildings, bridges, and stadiums. Its strength-to-weight ratio makes it ideal for high-rise buildings, where floor layouts demand efficient load-bearing solutions.

In the automotive industry, CHS is increasingly being used for chassis components and frames due to its ability to absorb impact effectively while maintaining lightweight characteristics. Additionally, it finds applications in manufacturing furniture and equipment, where design flexibility and strength are essential.

Fabrication and Production

Manufacturing CHS steel sections involves advanced techniques that ensure consistent quality and precision. The process typically starts with the production of steel sheets, which are then rolled into circular shapes and welded along the seam. Various dimensions and wall thicknesses can be produced to meet specific engineering requirements. Surface treatments, such as galvanization or painting, can also be applied to enhance corrosion resistance and durability, ensuring longevity in harsh environments.

Sustainability Considerations

As the construction industry moves towards more sustainable practices, the use of CHS steel aligns with eco-friendly initiatives. The reduced material consumption and lightweight structures contribute to lower carbon footprints during construction. Furthermore, steel is recyclable, and the use of recycled materials in producing CHS sections is increasingly common, promoting a circular economy within the steel industry.

Conclusion

In summary, Circular Hollow Section steel presents a host of advantages that make it a preferred option in various engineering and construction applications. Its structural efficiency, aesthetic versatility, and lightweight nature provide significant benefits, while its ability to be produced sustainably aligns with modern environmental standards. As technology continues to advance and design demands evolve, CHS steel is likely to remain a critical material in shaping the future of construction and manufacturing. Whether for robust structural framing or innovative architectural designs, CHS steel stands out as a powerhouse of modern building materials.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

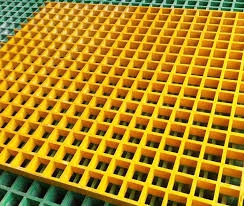

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025