loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Circular Hollow Section (CHS) Steel - Structural Efficiency and Versatility

Understanding Circular Hollow Section Steel

Circular Hollow Section (CHS) steel is a popular structural material utilized in a variety of construction applications. Its unique shape, characterized by a hollow circular profile, offers numerous benefits, making it an attractive choice for engineers and architects alike. This article delves into the properties, advantages, and typical applications of CHS steel.

One of the primary features of CHS steel is its strength-to-weight ratio. This type of steel section is strong yet lightweight, which allows for more efficient use of materials without compromising structural integrity. The circular design distributes loads evenly in all directions, making it highly effective in handling axial, bending, and torsional stresses. This uniform distribution of force makes CHS steel particularly suitable for applications subject to dynamic loads, such as in bridges and tall buildings.

Additionally, CHS steel is resistant to buckling, which is a common failure mode in structural components. Due to the absence of corners, CHS does not have points of stress concentration, which can weaken the material. This property allows CHS members to carry heavier loads and navigate through a variety of structural challenges. Moreover, the circular shape allows for easier connection and interfacing with other structural elements, facilitating complex designs and promoting architectural creativity.

Another significant advantage of using circular hollow sections is their aesthetic appeal. The smooth, continuous surface of CHS steel offers a modern and streamlined appearance, which can enhance the visual appeal of a structure. As such, they are often favored in applications where the aesthetic aspect is just as important as structural strength, such as in exposed frameworks and public art installations.

circular hollow section steel

In terms of sustainability, circular hollow section steel is an excellent option. Steel is a recyclable material, and the efficient use of CHS can lead to reduced waste in construction projects. CHS steel sections can be manufactured to specific lengths and dimensions, minimizing off-cuts and enabling better resource management during the building process.

CHS steel is commonly employed in various industrial sectors, including construction, automotive, and marine industries. In construction, they are widely used for columns, beams, and braces, particularly in high-rise buildings and bridges. In the automotive industry, their strength and lightweight properties make them ideal for manufacturing vehicle chassis and safety structures. The marine sector utilizes CHS steel for pontoons, buoys, and other structures that require durability and resistance to environmental factors.

Lastly, the fabrication of CHS steel is a straightforward process. With advancements in technology, CNC machines and automated welding techniques have significantly improved the precision and efficiency of producing CHS profiles. Such advancements contribute to the reliability of the final products, ensuring compliance with safety standards and regulations.

In summary, circular hollow section steel represents a versatile and efficient choice for modern construction and engineering projects. Its unique combination of strength, aesthetic appeal, and sustainability underscores its value in contemporary design. As industries continue to innovate and prioritize efficient materials, CHS steel will undoubtedly remain a pivotal element in shaping our built environment.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

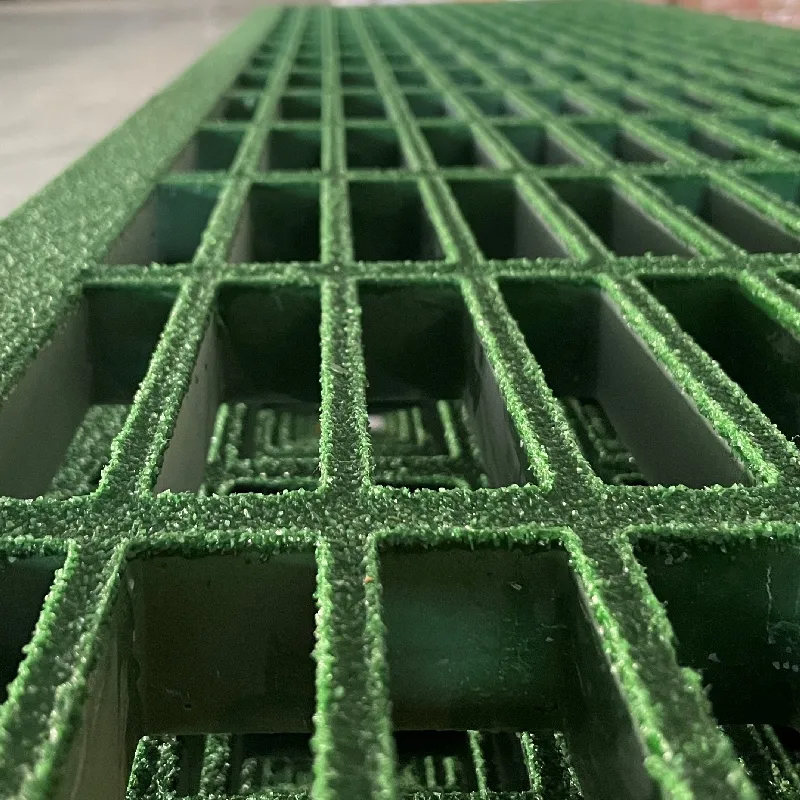

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025