loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

chs tube sizes

Understanding CHS Tube Sizes A Comprehensive Guide

When it comes to structural tubes, Circular Hollow Sections (CHS) stand out as one of the most widely utilized shapes in construction and engineering. CHS tubes are typically made of steel and are known for their strength, durability, and aesthetic appeal. In this article, we will delve into the various sizes of CHS tubes, their applications, and how to select the appropriate size for your specific needs.

What are CHS Tubes?

Circular Hollow Sections are hollow tubes with a constant circular cross-section. They are commonly available in a variety of diameters and wall thicknesses. The use of CHS tubes offers several advantages, including high resistance to torsion, excellent bending strength, and ease of welding and fabrication. These properties make CHS tubes ideal for a wide range of applications, from structural supports in buildings to components in vehicles.

Standard Sizes and Variations

CHS tubes are manufactured in accordance with various international standards, which dictate their dimensions and tolerances. Common standards include the Australian and New Zealand Standard AS/NZS 1163 and the American Institute of Steel Construction (AISC). Depending on the country and application, the specifications might vary.

1. Diameter The diameter of CHS tubes typically ranges from a few millimeters to over 600 mm (approximately 24 inches). Standard diameters often include sizes such as 50 mm, 100 mm, 150 mm, and up to 450 mm, catering to various structural requirements.

2. Wall Thickness The wall thickness can vary from 1.6 mm to 20 mm or more, depending on the load requirements and the specific application. Thicker walls will improve the tube’s resistance to buckling and bending, making them suitable for heavy-duty applications.

3. Length CHS tubes are generally available in standard lengths, with 6 meters being common. However, customization can often be accommodated by manufacturers to meet project-specific needs.

Applications of CHS Tubes

chs tube sizes

CHS tubes are versatile and employed across various sectors, including

- Construction Used for columns, beams, and scaffolding, where their strength and stability are essential. - Automotive In vehicle chassis and roll cages, CHS tubes provide high levels of collision protection due to their strength-to-weight ratio. - Furniture Design Their sleek appearance allows for aesthetic applications in furniture and decorative elements. - Infrastructure Used in frameworks for bridges, antenna masts, and telecommunications towers, where both strength and durability are required.

Selecting the Right CHS Tube Size

Choosing the right size of CHS tube is critical for the structural integrity of any project. Several factors should be considered

1. Load Requirements Determine the maximum load the tube needs to support. For heavier loads, opt for larger diameters and thicker walls.

2. Environmental Conditions Consider exposure to elements like moisture, corrosion, and temperature variations. If the tubes are going to be exposed to harsh environments, appropriate protective coatings or stainless materials may be necessary.

3. Design Specifications Consult engineering standards and codes relevant to your region or sector to ensure compliance. It’s essential to work closely with a structural engineer to adhere to industry safety standards.

4. Cost and Availability Finally, factor in the budget and availability of different sizes. Custom sizes may incur greater costs and longer lead times compared to standard sizes.

Conclusion

In conclusion, CHS tubes are an essential component in modern engineering and construction, offering a unique blend of strength, aesthetic appeal, and versatility. Understanding the various sizes and specifications of CHS tubes, along with their applications, helps in making informed decisions that enhance structural integrity and performance. Whether you are involved in a large construction project or a delicate design task, choosing the right CHS tube size is paramount to success. By considering factors such as load requirements, environmental conditions, and compliance standards, you can ensure that you select the ideal CHS tube for your needs.

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025

-

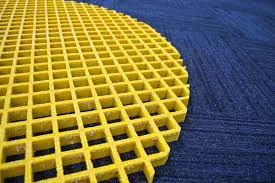

The Strength and Durability of FRP GratingNewsMay.21,2025

-

The Importance of Water Treatment Systems for Clean and Safe WaterNewsMay.21,2025

-

The Advantages of FRP Rebar for Construction ProjectsNewsMay.21,2025

-

Say Goodbye to Hard Water with a Reliable Water SoftenerNewsMay.21,2025

-

Maximize Your Water Storage with a Sectional Water TankNewsMay.21,2025

-

The Power of Filter VesselsNewsMay.19,2025