loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

chs pipe sizes

Understanding CHS Pipe Sizes A Comprehensive Overview

When it comes to construction and manufacturing, one of the vital components is piping. CHS, or Circular Hollow Sections, are widely used in various applications due to their strength, versatility, and aesthetic appeal. Understanding CHS pipe sizes is crucial for engineers, architects, and builders as they serve as the backbone of structural integrity in many designs.

What are CHS Pipes?

CHS pipes are hollow cylindrical sections made from steel, frequently employed in construction, engineering, and architectural applications. Their circular shape provides a unique set of advantages, including the ability to withstand larger loads, ease of fabrication, and resistance to buckling. Available in various materials, including mild steel and stainless steel, CHS pipes can be tailored to meet specific requirements for strength and durability.

Standard Sizes and Dimensions

CHS pipe sizes range widely, typically defined by their outer diameter (OD) and wall thickness. Commonly, these sizes are specified in millimeters (mm) or sometimes inches, depending on regional engineering standards. The most frequently available diameter sizes start from as small as 20 mm up to 400 mm or more. The wall thickness can vary to enhance strength and performance based on the application.

To provide a frame of reference, a standard CHS pipe might come in sizes such as 75 mm, 100 mm, or even up to 300 mm in diameter, with wall thickness options ranging from 2.5 mm to 12 mm. It's essential to select the appropriate CHS size for the weight-bearing demands and environmental conditions of a particular project.

Applications of CHS Pipes

chs pipe sizes

CHS pipes find application in numerous fields. In construction, they are often utilized in structural frameworks, columns, and support beams. Their aesthetic appeal and strength make them popular in architectural designs. Furthermore, CHS pipes are increasingly utilized in the manufacturing of furniture and in infrastructure projects such as bridges, where their ability to distribute weight evenly is invaluable.

In industries such as automotive and aerospace, CHS pipes are also used because of their lightweight yet strong characteristics, aiding in the performance and efficiency of vehicles and aircraft.

The Importance of Correct Sizing

Selecting the correct CHS pipe size is integral to ensuring safety and compliance with relevant building codes. An incorrectly sized pipe may lead to structural failure or inefficiencies, underscoring the necessity of precise calculations and planning. Engineers often use software to simulate load-bearing conditions and determine the most suitable CHS sizes for specific applications.

Additionally, while purchasing CHS pipes, it's essential to consider the manufacturing standards such as AS/NZS 1163 or ASTM A500, which guarantee quality and performance in various environmental conditions.

Conclusion

In summary, CHS pipe sizes play a pivotal role in construction and engineering projects. Understanding the options available, their specifications, and applications is essential for making informed choices that ensure safety, efficiency, and aesthetic value in any build. Whether for a residential project or a large-scale infrastructure development, the right CHS pipe selection is fundamental to achieving lasting results.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

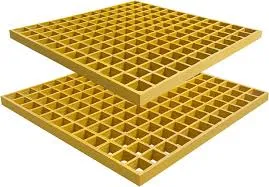

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025