loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Exploring the Applications and Benefits of CHS Pipe in Modern Construction

Understanding CHS % Pipe A Comprehensive Overview

In the world of piping systems, CHS (Circular Hollow Section) pipes have gained notable recognition across various industries for their structural integrity, versatility, and efficiency. These pipes have become indispensable in construction, manufacturing, and engineering applications. This article explores the significance of CHS pipes, their properties, advantages, and applications, providing a thorough understanding of this essential engineering material.

What is CHS Pipe?

CHS pipes are hollow cylindrical structures made from steel or other materials, characterized by their uniform round shape and thickness. They are often produced through the process of welding or extrusion. The term CHS is derived from their circular cross-section, which distinguishes them from other hollow sections, such as square or rectangular pipes. These pipes are available in various sizes, lengths, and wall thicknesses, making them adaptable to numerous building requirements.

Properties of CHS Pipes

1. Strength-to-Weight Ratio One of the most remarkable properties of CHS pipes is their high strength-to-weight ratio. They are designed to withstand significant loads while remaining lightweight, allowing for easier handling and installation. This property is particularly advantageous in construction and structural applications where optimizing material efficiency is crucial.

2. Uniform Distribution of Stress The circular shape of CHS pipes allows for a uniform distribution of stress across their surface, reducing the likelihood of weak points or failures. This property makes them a reliable choice for supporting loads in various building structures.

3. Resistance to Bending and Buckling CHS pipes maintain their shape and structural integrity under various loads, preventing bending or buckling. This resistance enhances their durability and longevity, making them an economically viable option in the long term.

4. Corrosion Resistance Many CHS pipes are coated or treated to resist corrosion, further extending their lifespan and reliability in harsh environments. This is particularly important in applications exposed to moisture or chemicals, such as in the construction of bridges or pipelines.

Advantages of CHS Pipes

chs pipe

1. Versatility CHS pipes are used across a myriad of applications, including structural frameworks, scaffolding, automotive components, and pipelines. Their adaptability to different environments and requirements makes them a popular choice in diverse industries.

2. Easy to Fabricate CHS pipes can be easily cut, welded, and joined with other materials, facilitating fabrication and installation. This ease of processing reduces overall project time and costs, which is a significant advantage for engineers and contractors.

3. Aesthetic Appeal The smooth and streamlined appearance of CHS pipes contributes to modern architectural designs. They can be incorporated into both structural and aesthetic elements, enhancing the overall visual appeal of buildings and structures.

4. Sustainability As the world shifts towards eco-friendly practices, CHS pipes made from recyclable materials are an excellent choice for sustainable construction. They can be recycled and repurposed, minimizing waste and supporting environmentally friendly building practices.

Applications of CHS Pipes

CHS pipes are utilized in a wide range of applications, some of which include

- Construction Used for structural supports, beams, columns, and bracing systems in residential and commercial buildings. - Scaffolding Commonly employed in temporary scaffolding systems for safe access and support during construction and maintenance. - Automotive Industry Used in manufacturing components like chassis, frames, and roll cages, where strength and weight reduction are critical. - Infrastructure Essential in creating bridges, towers, and other infrastructure that require robust and reliable support systems.

Conclusion

In summary, CHS pipes play a crucial role in modern engineering and construction, offering numerous advantages that cater to the demands of various industries. Their unique properties, such as strength, durability, versatility, and aesthetic appeal, make them a preferred choice for engineers and architects alike. As the construction industry continues to evolve, the significance of CHS pipes is expected to grow, solidifying their position as a cornerstone material in future engineering projects. Understanding CHS pipes can lead to more informed decisions in design and construction, ensuring successful outcomes in various applications.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

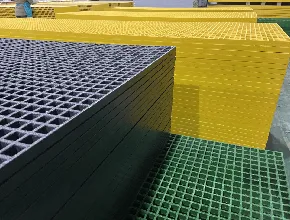

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025