loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Design and Analysis of Circular Hollow Sections in Structural Engineering Applications

Understanding Circular Hollow Sections (CHS) in Structural Engineering

Circular Hollow Sections (CHS) are a popular choice in structural engineering and design due to their unique properties and advantages. These sections are characterized by their hollow circular shape, providing high strength-to-weight ratios and structural integrity. As construction techniques and materials have evolved, the use of CHS has gained prominence in various applications, from commercial buildings to bridges and industrial structures.

Properties and Advantages of CHS

One of the primary advantages of CHS is its uniform strength distribution. Unlike other structural shapes, such as I-beams or rectangular hollow sections, the circular geometry of CHS allows for equal resistance to bending and torsion across all axes. This uniformity makes CHS particularly effective in load-bearing applications where multidirectional stresses are present.

Moreover, CHS offers excellent resistance to buckling, making it suitable for slender structures. This is an essential feature in high-rise buildings and towers, where stability against lateral loads, such as wind or seismic forces, is critical. The circular shape also minimizes stress concentrations, reducing the risk of material failure under varying load conditions.

Applications of CHS

The versatility of CHS enables its use across a wide range of applications. In architectural design, CHS is often employed in facades, canopies, and column structures due to its aesthetic appeal and structural benefits. In infrastructure, CHS is commonly used for bridges and transmission towers, where strength and durability are paramount. The hollow sections can also accommodate services like electrical conduits or drainage systems without compromising structural performance.

Material Considerations

chs circular hollow section

Typically, CHS is constructed from steel, which offers high tensile strength and durability. The use of steel not only enhances the structural capabilities of CHS but also ensures longevity and resilience against environmental factors. Additionally, advancements in steel manufacturing processes have led to the development of higher-grade steels, allowing for even thinner wall sections without sacrificing strength.

It is also worth noting that CHS can be fabricated from various materials, including aluminum and reinforced composites, depending on specific project requirements. The choice of material impacts the weight, cost, and overall performance of the CHS in its intended application.

Design and Engineering Challenges

Despite their advantages, designing with CHS presents particular challenges that engineers must address. One concern is the need for precise calculations regarding load distribution and joint connections, as the circular geometry can complicate traditional connection methods. Engineers often rely on advanced computational modeling and analysis to ensure that the structural design meets safety and performance standards.

Additionally, corrosion protection is a critical consideration, especially in exterior applications where CHS may be exposed to the elements. Various protective coatings and treatments can extend the lifespan of CHS structures, ensuring that they remain resilient over time.

Sustainability and Future Prospects

As the construction industry increasingly prioritizes sustainability, CHS holds promise as a material that can contribute to more environmentally friendly structures. The lightweight nature of CHS can lead to reduced material usage and lower transportation costs. Furthermore, steel is recyclable, making CHS a sustainable choice in design.

In conclusion, Circular Hollow Sections stand out as a robust, versatile, and aesthetically pleasing option in modern structural engineering. Their remarkable properties make them suitable for diverse applications, while the challenges they present can be managed through innovative engineering practices. As the industry continues to evolve, the significance of CHS in creating efficient, durable, and sustainable structures is expected to grow further. Engineers and architects will continue to explore the potential of CHS, pushing the boundaries of design and construction in the years to come.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

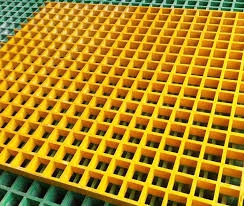

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025